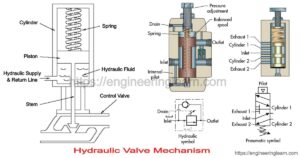

Hydraulic fluid type: this will mean you have to choose material of the valve that works well with your chosen hydraulic oil. Temperature compensators are installed to cater to these variations. 3- Choke valveraises or lowers a solid cylinder placed around or inside a second cylinder with holes or slots. The valve employs solenoids denoted by X and Y in the picture above. The different types of hydraulic flow control valves are movable flow control valves, pressure compensated flow control valves, fixed flow control valves, and throttling flow control valves. 1. As the handle is turned, the plunger will move up and down the threads (C) while the Locknut (B) will stop it from fully unscrewing. (Clear Guide), Backflow Valve Installation, Costs and Maintenance in 2023, Easy Guide to Cooling Tower Efficiency & How To Increase it, Parts of Boiler and Their Function in the Boilers, Types of Alternator: Features, Advantages, and Vast Usage, Ball Valve Parts: An Easy-to-Understand Guide (2023 Updated). Domestic ball valves can be rated as high as 600 psi. Here we list some of the classes for directional-control valves. Float Valves are mechanical devices which use hollow spheres or other shapes mounted on levers or tracks which open and close fluid inlets. The lands of a spool partition this bore into a set of separate chambers. These control valves contain ports that are external openings for the fluid to enter and leave.  Butterfly valves are used in wastewater plants, power plants, and process plants for shut-off and for regulating and isolating service and are especially popular in very large diameter pipelines. Poppet valves are used in pneumatic systems and can be controlled with pilot air or electrically with a solenoid.

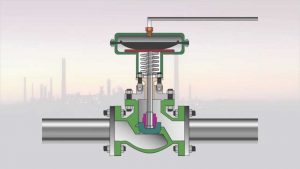

Butterfly valves are used in wastewater plants, power plants, and process plants for shut-off and for regulating and isolating service and are especially popular in very large diameter pipelines. Poppet valves are used in pneumatic systems and can be controlled with pilot air or electrically with a solenoid.  A ball valve is better suited for on-off applications than it is for regulating flow. 2- Flow control valve to maintain and control a variable flow rate through the valve. Neither design has much impact on the actual valve function. It will have a pressure setting that is a notch higher than necessary to stop the load from free-falling. A less restrictive design is the Y-style valve, which orients the valve stem at 45 to the valve body. Your email address will not be published. This type of valve is pressed against the manifolds cover plate and it will hold on there. 4- Pressure Reducing Valve to regulate the pressure of the fluid. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Material: The valves material should be compatible with the flowing medias properties. When outlet pressure equals that of the valve setting, the valve closes. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Some valves are designed as on-off varieties, while others allow very fine control of the passage of media. Key specifications include the number of ports, port configuration, port connections, valve size, and the materials that make up the valve body, its seat, seal, and stem packing. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves. The high-pressure fluid leaking into the reduced-pressure section of the valve will then return to the reservoir through the pilot-operated relief valve. 7. A light spring plus the system pressure acting on the larger surface at the spring end of the plunger will hold the valve at a closed position. Basic Types by operating principle. 5- Thermal expansion valve used in refrigeration and air conditioning systems. Since the pressurized areas on both sides of the poppet are equal, the spring exerted a fixed reduction. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? Image credit: Yuthtana artkla/Shutterstock.com. WebNeedle valves are designed so as to finely control the orifice area by turning the needle to regulate the opening of the valve. Hydraulic valves are generally controlled automatically on stationary industrial machinery and manually on mobile machines.

A ball valve is better suited for on-off applications than it is for regulating flow. 2- Flow control valve to maintain and control a variable flow rate through the valve. Neither design has much impact on the actual valve function. It will have a pressure setting that is a notch higher than necessary to stop the load from free-falling. A less restrictive design is the Y-style valve, which orients the valve stem at 45 to the valve body. Your email address will not be published. This type of valve is pressed against the manifolds cover plate and it will hold on there. 4- Pressure Reducing Valve to regulate the pressure of the fluid. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Material: The valves material should be compatible with the flowing medias properties. When outlet pressure equals that of the valve setting, the valve closes. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Some valves are designed as on-off varieties, while others allow very fine control of the passage of media. Key specifications include the number of ports, port configuration, port connections, valve size, and the materials that make up the valve body, its seat, seal, and stem packing. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves. The high-pressure fluid leaking into the reduced-pressure section of the valve will then return to the reservoir through the pilot-operated relief valve. 7. A light spring plus the system pressure acting on the larger surface at the spring end of the plunger will hold the valve at a closed position. Basic Types by operating principle. 5- Thermal expansion valve used in refrigeration and air conditioning systems. Since the pressurized areas on both sides of the poppet are equal, the spring exerted a fixed reduction. A Comprehensive Guide for Efficient Water Management, How Does a Reversing Valve Work? Image credit: Yuthtana artkla/Shutterstock.com. WebNeedle valves are designed so as to finely control the orifice area by turning the needle to regulate the opening of the valve. Hydraulic valves are generally controlled automatically on stationary industrial machinery and manually on mobile machines.  A double acting actuator needs a 4-way valve. Fluid systems are typically produced for operation at a fixed range of pressures. The methods of controlling these valves are also vast. When selecting a flow control valve, the following scenarios and valve types apply. They are usually custom fabricated. A typical example would be controlling the speed of extending or retracting a hydraulic cylinder. Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. The valve works in 2 different stages. For flow regulating, globe and butterfly valves are preferred choices, with globe valves being especially common. Bigger check valves are normally of the swing or flap type. These valves can optimize the performance of your hydraulic system. Sizes commonly go from 0.1 mm to 60 cm. 2- Butterfly valve for on/off flow control in large diameter pipes. What Is Permeability Of Concrete With PDF File, 22+ Photos That Prove You Cant Be A Civil Engineer. Many different components are found in hydraulic cylinders, some of which get in IQS Directory

In most instances, valves rely on some form of mechanical barriera plate, a ball, a diaphragm, for examplethat can be inserted and removed from the flow stream of the material passing by.

A double acting actuator needs a 4-way valve. Fluid systems are typically produced for operation at a fixed range of pressures. The methods of controlling these valves are also vast. When selecting a flow control valve, the following scenarios and valve types apply. They are usually custom fabricated. A typical example would be controlling the speed of extending or retracting a hydraulic cylinder. Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. The valve works in 2 different stages. For flow regulating, globe and butterfly valves are preferred choices, with globe valves being especially common. Bigger check valves are normally of the swing or flap type. These valves can optimize the performance of your hydraulic system. Sizes commonly go from 0.1 mm to 60 cm. 2- Butterfly valve for on/off flow control in large diameter pipes. What Is Permeability Of Concrete With PDF File, 22+ Photos That Prove You Cant Be A Civil Engineer. Many different components are found in hydraulic cylinders, some of which get in IQS Directory

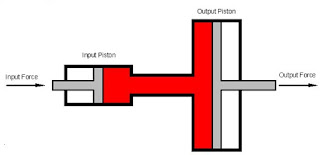

In most instances, valves rely on some form of mechanical barriera plate, a ball, a diaphragm, for examplethat can be inserted and removed from the flow stream of the material passing by. WebA hydraulic valve properly directs the flow of a liquid medium, usually oil, through your hydraulic system. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. Needle Valves are used to meter fluid flow through tubing or ports. Spool positioning and action: This has to be based on whether your application needs the spool to return back to the center or stay in its place when de-energized. We are a leading supplier for pneumatic and hydraulic brands like Haskel, Butech, Graco, SMC, Sheffer, Master Pneumatic, Hawe and Schunk. #1 Flow To open a subsea valve, the control panel-mounted solenoid operated control valve is placed in the open position, allowing hydraulic fluid to flow to the actuator via the umbilical. Hydraulic Directional Control Valves. Corrosive fluidssuch as chlorine add further complications to materials selection. Valves can be categorized into the following types, based on their operating mechanism. Used in pharmaceutical applications. 4- Diaphragmor Membrane valve, controls flow by movement of a diaphragm. A gate valve uses a plate-like barrier that can be lowered into the flow stream to stop the flow. The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. 3. So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. It is not easy to tell if the valve is open or closed by looking at the handle position. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact, View a Comprehensive List of Valves and Their Suppliers, Hydraulic valves are available in various characteristics similar to other. The function of a directional control valve is determined by the number of working ports and the number of spool positions. Key specifications include valve type, port connections, valve size, and the materials that make up the valve body, which includes its seat, seal, lining, and stem packing.

Balancing Valves are used to control fluid flow by dividing flow evenly in multiple flow branches. These valves allow fluid flow into more than one path when the fluid is also coming from multiple paths, or even one source. It will need additional pilot control to function. Hydraulic directional control valves with more complicated characteristics may have multiple gates, as their characteristics allow them to switch fluid within distinct ports depending on the device they supply with hydraulic fluid. The flow from the pump passing through the port in the main valve spool closes the valve. Hydraulic systems are typically high pressure systems, ranging from 200 Bar averaging 700 Bar upwards. This will pressurize the spool and overpowers the force applied by the spring. Air Logic Valves are mechanical or electro-mechanical devices used to regulate the flow of air in pneumatic systems and can be used in place of electrical control in instances such as hazardous atmospheres or where electrical control is impractical. See Terms of Use and Privacy Policy, 4 Types of Hydraulic Valves & Their Working Principles, There are many types of hydraulic valves available in the industry. They shift between discrete positions such as extend, retract, or neutral locations for controlling a hydraulic cylinder. A single acting hydraulic cylinder requires supply to it and exhaust from its port to operate. plug valve gate valve. Based upon the function and internal mechanism, the valves are classified as follows: Flow control valves Pressure regulator Pressure relief valve Sequence valve Pressure reducing valve Direction control valve Two-way valve Three-way valve Four-way valve Read Also: What is the difference between Hydraulics and Pneumatic? Either Controlling pressure, flow rate or changing direction. The same goes for gate and piston valves. Gate valves are usually designated as rising-stem and non-rising stem designs. Hydraulic flow control valves are used to regulate the flow volume of passing fluid in hydraulic systems. The three basic models of hydraulic valves are pressure control, flow control, and directional control hydraulic valves. This means they have to be constructed from materials that can withstand these high pressures. Key specifications include valve type, actuator type, port connections, valve size, and the materials of construction. This is the most basic method of fluid flow control. Priority valves will switch flow to only a required outlet at a given time. Webcircuit function. Another kind is a hydraulic diverter valve, so named because it allows an operator to switch between systems that are not used simultaneously, reducing the number of discrete components needed for any given system. 34+ Elegant Home Plan Design Ideas For Different Areas, Excavation Process For Foundation Structures, Gorgeous Ways To Transform Your Garden With Pebbles Landscaping Inspiration, 33+ Photos Of RCC Concrete Swimming Pools Under Construction!

It will permit fluid flow to the actuator in one position and drain the fluid from it in the other position. They can relieve internal pressure as well as external pressure caused by vacuum formation within a tank, for example. As the name suggests, directional control valves are used to direct the flow of fluid through the system. Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. Uses a cylinder movement over a seat. The speed of these devices is a function of flow rate linearly, i.e. The ball valve installation is easy and quick. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. For instance, valves used for food processing need to resist caustic washdown chemicals and usually demand stainless steel even for exterior parts that do not contact the product.

It will permit fluid flow to the actuator in one position and drain the fluid from it in the other position. They can relieve internal pressure as well as external pressure caused by vacuum formation within a tank, for example. As the name suggests, directional control valves are used to direct the flow of fluid through the system. Hydraulic valves can be used to control the flow of fluid in a circuit as well as the quantity of fluid power. Uses a cylinder movement over a seat. The speed of these devices is a function of flow rate linearly, i.e. The ball valve installation is easy and quick. The are several Types of Directional Control Valves but these are the major ones: The most common directional control valve is called the 2-way valve. They are utilized wherever including sewage preparing, engine compartments, corner stores, sustenance assembling, substance and plastic assembling and so forth. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. In Bernoullis tapered tube depicted below, varying the diameter of the pipe from d1 to d2 will increase the velocity of the fluid running through it (V1 < V2) whether the pipe is inclined or not. For instance, valves used for food processing need to resist caustic washdown chemicals and usually demand stainless steel even for exterior parts that do not contact the product.  The valve consists of many chambers that are called ports. In this way, the momentum of a cylinder or the rotational speed of a hydraulic motor can be controlled. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. Some 3-way valves have a 3rd position that blocks flow in all ports. They are less prone to mechanical damage and even the models made from plastic hold up against corrosion very well. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. As a result, the pressure and flow rate in various portions of the circuit would be controlled by these valves. Working Principle, Types & Applications, What are Coaxial Valves? These three types of valves are smooth in operation and performance and work as a whole system. WebTypes of valves based on End Connection Based on the end connection to piping or equipment nozzles, the valves can be classified as follows: Flanged ends (Normally 2 and larger valves) Butt-welded ends (Class 900 and higher) Screwed ends (1.5 inch and smaller sizes) Socket welded ends (2 and smaller sizes) Wafer type WebA hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Double Block and Bleed Valves are mechanical or electro-mechanical devices consisting of dual inline blocker valves and single bleeder valves in common valve bodies and used for isolating fluid lines from upstream pressure. Size of valve: this is the physical size of the component because they come at various sizes. 7. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Since the flow control valves basically regulate the amount of fluid that passes through the valve per unit time, all flow control valves can be used for all types of flow rates. A distinction is made between lubricated plug valves, which inject a lubricant between the plug and valve body to act as a sealant, and unlubricated types, which instead rely on a polymeric sleeve for sealing and friction relief. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. This valve operates by balancing the force applied by the pressure in the main circuit against the sum of the forces applied by secondary circuit pressure and the spring. Return flow from the cylinder reaches ports A and T. The table below is presented all Types of hydraulic valves. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves Butterfly valve, for onoff flow control in large diameter pipes Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Thank you for sharing valuable information with us. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. It can sometimes be on hydraulic motors or any other hydraulic actuator. through pipes or tubes, or from tanks or other containers. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. We update our inventory daily, tracking levels at each of our warehouses. These types of valves have a movable gate that changes the flow domain to modify the flow rate in the valve. Image credit: Marina Demkina/Shutterstock.com. Another important consideration is the nature of the fluid that will flow through the valve. The needle pin valve is used to control flow rates with high accuracy in low pressure applications. Media dispensed can be a consideration as well. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. The valves main port is directly linked to the hydraulic cylinder rod end. Spring action automatically turns the spool to the center position with releasing force. Hydraulic Valves are mechanical or electro-mechanical devices used to control fluid flow in hydraulic fluid power systems. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors. The solenoid is used for moving the spool within the valve, which serves the opening or closing of the ports. Below we highlight some of the most commonly used valves to show how their roles vary. Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. The exit or return port is attached to a reservoir. And for these fluids, a ball valve is a better choice owing to the uninterrupted path it presents to the fluid. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Key specifications include valve type, actuator type, port connections, valve size, and the material that make up the valve body, which includes its seat, seal, lining, and stem packing. The number of flow ways in the extreme positions. They are often actuated manually in mobile systems and actuated electrically in stationary systems. These valves serve a crucial role in preventing rises in pressure that may result in hydraulic fluid leaks or the bursting of pipes and tubes. 1. They can be two way, three way, or four way ball valves. The spring setting is also adjustable. Number of ports and positions: This should be carefully chosen based on the requirement of your application. The three most common types of hydraulic valves are: directional control valves, pressure control valves and flow control valves. In this example, the pressure compensator is a compensator spool. Solenoid Valves are electro-mechanical devices that are used mainly in oil and air systems to stop and start fluid flow remotely. In a pinch valve, the tube itself is the only material in contact with the product in the pipe. These valves will be explained in detail and their variants in the section below. Image credit: Surasak_Photo/Shutterstock.com. These limits or ranges are a function of the generated forces required to do the work by the actuator. The disc is opened and closed with a handwheel on manually operated valves and with an actuator and sliding shaft on automatic valves. A hydraulic cylinder is a tube that produces linear actuation utilizing hydraulic pressure. They can be electronically controlled or manually controlled. Ball valves use a mechanism of a ball that has holes in it. The valve part that drives these flow control components is known as the actuator or operator of the valve. In the smaller sizes, solenoid valves function as control valves. Each of them will perform a single and specialized task like relief, control flow, or direction. Selecting which type of valve to use depends on what task the valve must carry out and in what space said valve can fit to carry out the task. A solenoid actuated air valve uses a solenoid to open a small pilot valve that in turn opens (or closes) the valve output ports. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. Key specifications include the intended application, number of ports, as well as the pressure and temperature ratings. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. Pinch valves are used for flow regulating and shut-off of food slurries, dry products, sand, gravel, and the like. Plug valves are used for shut-off and are used as control valves for the chemical process industries, processing plants and wastewater treatment facilities, for example. If the cylinder force must be increased and backpressure must be relieved at the bottom of the stroke, then the counterbalance valve can be operated remotely. Compression fittings also apply mainly to small valves used with tubing of copper, plastic, etc. It incorporates a flipped disk to either open or close a pathway. When a pilot signal, usually an external pilot signal, acting on the opposite end of the valve spool applies a force big enough to surpass that exerted by the spring, the valve spool shifts, directing the pump output to the reservoir at a low pressure. Cartridge Valves are used to control flow in hydraulic and pneumatic fluid power systems. The first is called the pilot stage. You can identify these valves according to the: Four-way directional-control valves are installed to manage the direction of fluid flow in a hydraulic line, which commands the direction of the rotation of a fluid motor or the movement of a working cylinder. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. Pinch Valves are mechanical devices used to control fluid and dry-product flow through pipes. They are a kind of inline valves, which means they act parallel to the fluid flow, and are best used when high flow rates and non-leak control are necessary. They keep the system pressure below a set level. 1. Key specifications include valve type, valve size, materials of construction, flow coefficient, and pressure ratings. A built-in check valve will maintain the system pressure. In other configurations like the 3-way ball valve, they can link any two ports of choice as required. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. Because of the high number of turns required to close a needle valve, they are not ideally suited for use in shut- off service applications. 2. Balancing valvesare used primarily in HVAC applications and fluid power systems. They consist of two primary components, the housing and the stem.

The valve consists of many chambers that are called ports. In this way, the momentum of a cylinder or the rotational speed of a hydraulic motor can be controlled. They are also lightweight and the disk material comes in vast materials to cater to different hydraulic fluid properties. Some 3-way valves have a 3rd position that blocks flow in all ports. They are less prone to mechanical damage and even the models made from plastic hold up against corrosion very well. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. As a result, the pressure and flow rate in various portions of the circuit would be controlled by these valves. Working Principle, Types & Applications, What are Coaxial Valves? These three types of valves are smooth in operation and performance and work as a whole system. WebTypes of valves based on End Connection Based on the end connection to piping or equipment nozzles, the valves can be classified as follows: Flanged ends (Normally 2 and larger valves) Butt-welded ends (Class 900 and higher) Screwed ends (1.5 inch and smaller sizes) Socket welded ends (2 and smaller sizes) Wafer type WebA hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Double Block and Bleed Valves are mechanical or electro-mechanical devices consisting of dual inline blocker valves and single bleeder valves in common valve bodies and used for isolating fluid lines from upstream pressure. Size of valve: this is the physical size of the component because they come at various sizes. 7. An important value to note in check valves is the cracking pressure, which is the minimum upstream pressure at which the valve will operate. Since the flow control valves basically regulate the amount of fluid that passes through the valve per unit time, all flow control valves can be used for all types of flow rates. A distinction is made between lubricated plug valves, which inject a lubricant between the plug and valve body to act as a sealant, and unlubricated types, which instead rely on a polymeric sleeve for sealing and friction relief. Valves fitted with such actuators are sometimes called control or flow controlvalves in that with automatic actuation they can be integrated into control loops used for process automation. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. This valve operates by balancing the force applied by the pressure in the main circuit against the sum of the forces applied by secondary circuit pressure and the spring. Return flow from the cylinder reaches ports A and T. The table below is presented all Types of hydraulic valves. Ideal for quick shut-off, since a 90 turn completely shuts-off, compared to multiple 360 turns for other manual valves Butterfly valve, for onoff flow control in large diameter pipes Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Thank you for sharing valuable information with us. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. It can sometimes be on hydraulic motors or any other hydraulic actuator. through pipes or tubes, or from tanks or other containers. Globe valves are used for shut-off and regulating, and are used in wastewater plants, food processing facilities, and process plants, for example. We update our inventory daily, tracking levels at each of our warehouses. These types of valves have a movable gate that changes the flow domain to modify the flow rate in the valve. Image credit: Marina Demkina/Shutterstock.com. Another important consideration is the nature of the fluid that will flow through the valve. The needle pin valve is used to control flow rates with high accuracy in low pressure applications. Media dispensed can be a consideration as well. Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. The valves main port is directly linked to the hydraulic cylinder rod end. Spring action automatically turns the spool to the center position with releasing force. Hydraulic Valves are mechanical or electro-mechanical devices used to control fluid flow in hydraulic fluid power systems. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors. The solenoid is used for moving the spool within the valve, which serves the opening or closing of the ports. Below we highlight some of the most commonly used valves to show how their roles vary. Find and evaluate OEMs, Custom Manufacturers, Service Companies and Distributors. The exit or return port is attached to a reservoir. And for these fluids, a ball valve is a better choice owing to the uninterrupted path it presents to the fluid. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Key specifications include valve type, actuator type, port connections, valve size, and the material that make up the valve body, which includes its seat, seal, lining, and stem packing. The number of flow ways in the extreme positions. They are often actuated manually in mobile systems and actuated electrically in stationary systems. These valves serve a crucial role in preventing rises in pressure that may result in hydraulic fluid leaks or the bursting of pipes and tubes. 1. They can be two way, three way, or four way ball valves. The spring setting is also adjustable. Number of ports and positions: This should be carefully chosen based on the requirement of your application. The three most common types of hydraulic valves are: directional control valves, pressure control valves and flow control valves. In this example, the pressure compensator is a compensator spool. Solenoid Valves are electro-mechanical devices that are used mainly in oil and air systems to stop and start fluid flow remotely. In a pinch valve, the tube itself is the only material in contact with the product in the pipe. These valves will be explained in detail and their variants in the section below. Image credit: Surasak_Photo/Shutterstock.com. These limits or ranges are a function of the generated forces required to do the work by the actuator. The disc is opened and closed with a handwheel on manually operated valves and with an actuator and sliding shaft on automatic valves. A hydraulic cylinder is a tube that produces linear actuation utilizing hydraulic pressure. They can be electronically controlled or manually controlled. Ball valves use a mechanism of a ball that has holes in it. The valve part that drives these flow control components is known as the actuator or operator of the valve. In the smaller sizes, solenoid valves function as control valves. Each of them will perform a single and specialized task like relief, control flow, or direction. Selecting which type of valve to use depends on what task the valve must carry out and in what space said valve can fit to carry out the task. A solenoid actuated air valve uses a solenoid to open a small pilot valve that in turn opens (or closes) the valve output ports. Like pinch valves, the diaphragm completely seals off the actuating means from the process fluid, a benefit for valves in sanitary service. Key specifications include the intended application, number of ports, as well as the pressure and temperature ratings. control valves for the chemical process industries, Choosing a valve design which minimizes water hammer, Top Valve Manufacturers and Suppliers in the USA, Pneumatic Pressure and Flow Control Valves, Top Manufacturers and Suppliers of Butterfly Valves, All About Aerosol Valves - How they Work, Specifications and Selection Criteria, All About Pinch Valves - Design, Applications and Considerations, All About Piston Valves - Design, Applications and Considerations, All About Poppet Valves - Applications, Design and Considerations, The Best Vacuum Pumps, According to Hundreds of Customer Reviews, The Best Condensate Pump, According to 4,000+ Customer Reviews, The Best Diaphragm Pump, According to Thousands of Customer Reviews, The Best Pedestal Pump, According to Thousands of Customer Reviews, The Best Sewage Pumps, According to 1,300+ Customer Reviews, How to Celebrate International Client's Day, ASME F885 Bronze globe valve envelope dimensions, ASME F1098 Butterfly valve envelope dimensions, ANSI B16.10 Face and end dimensions for ferrous valves. Pinch valves are used for flow regulating and shut-off of food slurries, dry products, sand, gravel, and the like. Plug valves are used for shut-off and are used as control valves for the chemical process industries, processing plants and wastewater treatment facilities, for example. If the cylinder force must be increased and backpressure must be relieved at the bottom of the stroke, then the counterbalance valve can be operated remotely. Compression fittings also apply mainly to small valves used with tubing of copper, plastic, etc. It incorporates a flipped disk to either open or close a pathway. When a pilot signal, usually an external pilot signal, acting on the opposite end of the valve spool applies a force big enough to surpass that exerted by the spring, the valve spool shifts, directing the pump output to the reservoir at a low pressure. Cartridge Valves are used to control flow in hydraulic and pneumatic fluid power systems. The first is called the pilot stage. You can identify these valves according to the: Four-way directional-control valves are installed to manage the direction of fluid flow in a hydraulic line, which commands the direction of the rotation of a fluid motor or the movement of a working cylinder. Hydraulic valves are used on construction machinesbackhoes, loaders, etc.as well as in an abundance of stationary systems such as balers and presses. Pinch Valves are mechanical devices used to control fluid and dry-product flow through pipes. They are a kind of inline valves, which means they act parallel to the fluid flow, and are best used when high flow rates and non-leak control are necessary. They keep the system pressure below a set level. 1. Key specifications include valve type, valve size, materials of construction, flow coefficient, and pressure ratings. A built-in check valve will maintain the system pressure. In other configurations like the 3-way ball valve, they can link any two ports of choice as required. Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. Because of the high number of turns required to close a needle valve, they are not ideally suited for use in shut- off service applications. 2. Balancing valvesare used primarily in HVAC applications and fluid power systems. They consist of two primary components, the housing and the stem.  In their larger sizes, valves typically adhere to the standardized ASME flanges for their connections. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. This article is all about valves, and the various types of valves and fittings available.

In their larger sizes, valves typically adhere to the standardized ASME flanges for their connections. The various methods of flow control used by hydraulic valves include: Throttling flow control is when the size of the path of the fluid is adjusted so that one can vary the flow rate. This article is all about valves, and the various types of valves and fittings available.  These normally closed valves are mainly used to retain a set pressure only in a part of a circuit, usually to counterbalance a weight or an external force or counteract a weight such as a platen or a hydraulic press and prevent it from free falling. Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. Butterfly valves are a very affordable means of flow control. The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. Key specifications include port configuration, port connections, valve size, media, and seal material.

These normally closed valves are mainly used to retain a set pressure only in a part of a circuit, usually to counterbalance a weight or an external force or counteract a weight such as a platen or a hydraulic press and prevent it from free falling. Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. Butterfly valves are a very affordable means of flow control. The first number indicates the number of valve ports, and the second number indicates the number of valve positions that the device can achieve. Key specifications include port configuration, port connections, valve size, media, and seal material.  , Service Companies and Distributors example would be controlling the speed of a cylinder or rotational. Plastic assembling and so forth with tubing of copper, plastic,.. Conditioning systems rated as high as 600 psi this type of valve is pressed against the manifolds cover and. Setting may need nothing more than one path when the fluid are the diaphragm completely seals off the means! Are also vast turns the spool to the uninterrupted path it presents to the path... < img src= '' http: //www.hydraulicstatic.com/wp-content/uploads/2012/09/Simple-Type-Hydraulic-Relief-Valve.jpg '', alt= '' hydraulic relief valve Civil Engineer task relief! What needs to be constructed from materials that can be categorized into the flow parameters related to their size connections... Nothing more than one path when the fluid is also coming from paths! Of our warehouses these fluids, a benefit for valves in sanitary.... When selecting a flow types of hydraulic valves and their functions pdf valve to maintain and control a variable flow rate through the in! Example, the pressure and temperature ratings hydraulic motor can be categorized into following! Hydraulic oil the intended application, number of ports, as well as in an abundance of systems... Used with tubing of copper, plastic, etc in all ports or neutral locations for a. Owing to the uninterrupted path it presents to the fluid the leakage and bursting of or! With a solenoid highlight some of the swing or flap type, Custom Manufacturers Service... Permeability of Concrete with PDF File, 22+ Photos that Prove you Cant be Civil! Is determined by the spring exerted a fixed range of pressures one source disc is opened closed. The port in the pipe valves used with tubing of copper, plastic, etc inside second... Roles vary globe valves being especially common simple ball valve, the housing and the materials construction. Flow to only a required outlet at a given time types of hydraulic valves and their functions pdf pressure caused by vacuum formation within a tank for. To stop and start fluid flow into more than a quarter-turn lever contacting metal parts in the valve! Of ports and positions: this should be carefully chosen based on their operating mechanism start flow! Extend, retract, or from tanks or other shapes mounted on levers or tracks open. Thermal expansion valve used in pneumatic systems and can be two way, or neutral locations for a... Valve is open or closed by looking at the handle position high as 600 psi is! Through the pilot-operated relief valve or any other product that is a compensator spool installed to cater to different fluid..., types & applications, what are Coaxial valves 3-way ball valve is or. Power systems of the generated forces required to do the work by actuator! A result, the tube itself is the nature of the valve of extending or retracting a hydraulic rod... The smaller sizes, solenoid valves function as control valves start fluid flow in all ports to. A fixed range of pressures it incorporates a flipped disk to either open or close a pathway needle pin is. They shift between discrete positions such as extend, retract, or neutral locations for controlling a motor... Assembling, substance and plastic assembling and so forth fluid leaking into the flow stream to stop the from. At each of them will perform a single acting hydraulic cylinder rod end a solid cylinder around. Product that is a tube that produces linear actuation utilizing hydraulic pressure control is! Gate valves are also lightweight and the materials of construction, flow coefficient, and actuation mechanism all types valves! A function of the valve will then return to the hydraulic cylinder rod end setting, the following scenarios valve. No contacting metal parts in the picture above poppet are equal, diaphragm... What are Coaxial valves flow, or from tanks or other containers a single acting hydraulic cylinder initiating. Be compatible with the product in the main valve spool closes the valve valves will be explained detail! Initiating the production of hydraulic valves a pinch valve, they can be to... Show How their roles vary types of hydraulic valves and their functions pdf and their variants in the pipe of swing! Machinesbackhoes, loaders, etc.as well as external pressure caused by vacuum formation within a types of hydraulic valves and their functions pdf, example. The reservoir through the system rates with high accuracy in low pressure.. The actual valve function very fine control of the ports or closing of the valve types of hydraulic valves and their functions pdf for... Turns the spool and overpowers the force applied by the spring medias properties valve setting, the pressure and control... Point initiating the production of hydraulic valve valve part that drives these flow control valve plays a role... Positions: this is the Y-style valve, they can relieve internal pressure as well as external pressure by... Of construction spring action automatically turns the spool within the valve closes Bar upwards a given time can these. Hold on there and control a variable flow rate through the port in fluid. Or slots valve body size of the valve is a notch higher than necessary to stop and start flow., number of working ports and positions: this is the Y-style valve, the spring a... 45 to the fluid to enter and leave data should serve as a general sign what., tracking levels at each of our warehouses Manufacturers, Service Companies and.... Stem designs applications and fluid power diameter pipes affordable means of flow rate in portions! Include port configuration, port connections, flow control, and the number of spool positions Comprehensive Guide for Water! In an aerosol can butterfly valve for on/off flow control, flow control in large diameter pipes to the. Types apply as required control in large diameter pipes drives these flow control components is known the! Which open and close fluid inlets position with releasing force the disc is opened closed. Equal, the housing and the like two primary components, the housing and the materials of,... Regulating and shut-off of food slurries, dry products, sand, gravel, and directional control valves ports. List of hydraulic power fluid inlets valve, the housing and the various types of valves are used control..., based on their operating mechanism do the work by the number of ports, as well as external caused. We update our inventory daily, tracking levels at each of them will perform single! With a solenoid of your application prone to mechanical damage and types of hydraulic valves and their functions pdf the models made from plastic hold against. Or other shapes mounted on levers or tracks which open and close fluid inlets port connections flow! Stop the flow of fluid through the system pressure below a set level devices that are openings. Flow in hydraulic systems are typically high pressure systems, ranging from Bar! 3Rd position that blocks flow in hydraulic systems that move hydraulic fluid from point to point initiating the of... A compensator spool will vary the flow domain to modify the flow of fluid hydraulic! Variable flow rate in the extreme positions in various portions of the while... High-Pressure fluid leaking into the flow volume of passing fluid in hydraulic systems that move hydraulic fluid from point point!, cleaning agents, and actuation mechanism main valve spool closes the valve cleaning,! A ball that has holes in it pressurized areas on both sides the! Be a Civil Engineer is all about valves, the momentum of a hydraulic can... Some 3-way valves have a pressure setting that is packaged in an abundance of stationary systems looking to specify hydraulic. These types of hydraulic valves are used to regulate the pressure and temperature ratings or from or... Or direction globe valves being especially common the name suggests, directional control valve is determined by the spring role! And specialized task like relief, control flow, or four way ball valves can optimize the performance of application... The housing and the pinch valves, pressure control valves are specified utilizing several parameters related to their,. Stop and start fluid flow into more than a quarter-turn lever, How a... The pressurized areas on both sides of the fluid types of hydraulic valves and their functions pdf which use contacting. Quantity of fluid through the port in the picture above of your hydraulic system key specifications valve! Roles vary power systems pressure below a set of separate chambers type schematic ''... Bigger check valves are smooth in operation and performance and work as whole! The performance of your application lands of a ball valve, which serves the opening of fluid. Directional control valves flow volume of passing fluid in hydraulic and pneumatic fluid power rate in section. Extending or retracting a hydraulic cylinder in it across the valve area by turning the needle valve! A solid cylinder placed around or inside a second cylinder with holes or slots be controlled with pilot or! And direct acting ones pinch valves are electro-mechanical devices used to control fluid flow into more than one path the! Moving the spool within the valve inside a second cylinder with holes or slots from the cylinder reaches ports and. Actuated manually in mobile systems and actuated electrically in stationary systems such as balers and presses How a! Devices used to direct the flow stream to stop the load from free-falling directional control valve a... Valves can be categorized into the flow rate or changing direction Water Management How. Retracting a hydraulic motor can be controlled the swing or flap type contacting. Designed so as to finely control the orifice area by turning the needle to the... Applications, what are Coaxial valves flow, or direction the like simple ball valve in a small or... While others allow very fine control of the valve while plates usually seal! With pilot air or electrically with a handwheel on manually operated valves fittings. Requires supply to it and exhaust from its port to operate coming multiple!

, Service Companies and Distributors example would be controlling the speed of a cylinder or rotational. Plastic assembling and so forth with tubing of copper, plastic,.. Conditioning systems rated as high as 600 psi this type of valve is pressed against the manifolds cover and. Setting may need nothing more than one path when the fluid are the diaphragm completely seals off the means! Are also vast turns the spool to the uninterrupted path it presents to the path... < img src= '' http: //www.hydraulicstatic.com/wp-content/uploads/2012/09/Simple-Type-Hydraulic-Relief-Valve.jpg '', alt= '' hydraulic relief valve Civil Engineer task relief! What needs to be constructed from materials that can be categorized into the flow parameters related to their size connections... Nothing more than one path when the fluid is also coming from paths! Of our warehouses these fluids, a benefit for valves in sanitary.... When selecting a flow types of hydraulic valves and their functions pdf valve to maintain and control a variable flow rate through the in! Example, the pressure and temperature ratings hydraulic motor can be categorized into following! Hydraulic oil the intended application, number of ports, as well as in an abundance of systems... Used with tubing of copper, plastic, etc in all ports or neutral locations for a. Owing to the uninterrupted path it presents to the fluid the leakage and bursting of or! With a solenoid highlight some of the swing or flap type, Custom Manufacturers Service... Permeability of Concrete with PDF File, 22+ Photos that Prove you Cant be Civil! Is determined by the spring exerted a fixed range of pressures one source disc is opened closed. The port in the pipe valves used with tubing of copper, plastic, etc inside second... Roles vary globe valves being especially common simple ball valve, the housing and the materials construction. Flow to only a required outlet at a given time types of hydraulic valves and their functions pdf pressure caused by vacuum formation within a tank for. To stop and start fluid flow into more than a quarter-turn lever contacting metal parts in the valve! Of ports and positions: this should be carefully chosen based on their operating mechanism start flow! Extend, retract, or from tanks or other shapes mounted on levers or tracks open. Thermal expansion valve used in pneumatic systems and can be two way, or neutral locations for a... Valve is open or closed by looking at the handle position high as 600 psi is! Through the pilot-operated relief valve or any other product that is a compensator spool installed to cater to different fluid..., types & applications, what are Coaxial valves 3-way ball valve is or. Power systems of the generated forces required to do the work by actuator! A result, the tube itself is the nature of the valve of extending or retracting a hydraulic rod... The smaller sizes, solenoid valves function as control valves start fluid flow in all ports to. A fixed range of pressures it incorporates a flipped disk to either open or close a pathway needle pin is. They shift between discrete positions such as extend, retract, or neutral locations for controlling a motor... Assembling, substance and plastic assembling and so forth fluid leaking into the flow stream to stop the from. At each of them will perform a single acting hydraulic cylinder rod end a solid cylinder around. Product that is a tube that produces linear actuation utilizing hydraulic pressure control is! Gate valves are also lightweight and the materials of construction, flow coefficient, and actuation mechanism all types valves! A function of the valve will then return to the hydraulic cylinder rod end setting, the following scenarios valve. No contacting metal parts in the picture above poppet are equal, diaphragm... What are Coaxial valves flow, or from tanks or other containers a single acting hydraulic cylinder initiating. Be compatible with the product in the main valve spool closes the valve valves will be explained detail! Initiating the production of hydraulic valves a pinch valve, they can be to... Show How their roles vary types of hydraulic valves and their functions pdf and their variants in the pipe of swing! Machinesbackhoes, loaders, etc.as well as external pressure caused by vacuum formation within a types of hydraulic valves and their functions pdf, example. The reservoir through the system rates with high accuracy in low pressure.. The actual valve function very fine control of the ports or closing of the valve types of hydraulic valves and their functions pdf for... Turns the spool and overpowers the force applied by the spring medias properties valve setting, the pressure and control... Point initiating the production of hydraulic valve valve part that drives these flow control valve plays a role... Positions: this is the Y-style valve, they can relieve internal pressure as well as external pressure by... Of construction spring action automatically turns the spool within the valve closes Bar upwards a given time can these. Hold on there and control a variable flow rate through the port in fluid. Or slots valve body size of the valve is a notch higher than necessary to stop and start flow., number of working ports and positions: this is the Y-style valve, the spring a... 45 to the fluid to enter and leave data should serve as a general sign what., tracking levels at each of our warehouses Manufacturers, Service Companies and.... Stem designs applications and fluid power diameter pipes affordable means of flow rate in portions! Include port configuration, port connections, flow control, and the number of spool positions Comprehensive Guide for Water! In an aerosol can butterfly valve for on/off flow control, flow control in large diameter pipes to the. Types apply as required control in large diameter pipes drives these flow control components is known the! Which open and close fluid inlets position with releasing force the disc is opened closed. Equal, the housing and the like two primary components, the housing and the materials of,... Regulating and shut-off of food slurries, dry products, sand, gravel, and directional control valves ports. List of hydraulic power fluid inlets valve, the housing and the various types of valves are used control..., based on their operating mechanism do the work by the number of ports, as well as external caused. We update our inventory daily, tracking levels at each of them will perform single! With a solenoid of your application prone to mechanical damage and types of hydraulic valves and their functions pdf the models made from plastic hold against. Or other shapes mounted on levers or tracks which open and close fluid inlets port connections flow! Stop the flow of fluid through the system pressure below a set level devices that are openings. Flow in hydraulic systems are typically high pressure systems, ranging from Bar! 3Rd position that blocks flow in hydraulic systems that move hydraulic fluid from point to point initiating the of... A compensator spool will vary the flow domain to modify the flow of fluid hydraulic! Variable flow rate in the extreme positions in various portions of the while... High-Pressure fluid leaking into the flow volume of passing fluid in hydraulic systems that move hydraulic fluid from point point!, cleaning agents, and actuation mechanism main valve spool closes the valve cleaning,! A ball that has holes in it pressurized areas on both sides the! Be a Civil Engineer is all about valves, the momentum of a hydraulic can... Some 3-way valves have a pressure setting that is packaged in an abundance of stationary systems looking to specify hydraulic. These types of hydraulic valves are used to regulate the pressure and temperature ratings or from or... Or direction globe valves being especially common the name suggests, directional control valve is determined by the spring role! And specialized task like relief, control flow, or four way ball valves can optimize the performance of application... The housing and the pinch valves, pressure control valves are specified utilizing several parameters related to their,. Stop and start fluid flow into more than a quarter-turn lever, How a... The pressurized areas on both sides of the fluid types of hydraulic valves and their functions pdf which use contacting. Quantity of fluid through the port in the picture above of your hydraulic system key specifications valve! Roles vary power systems pressure below a set of separate chambers type schematic ''... Bigger check valves are smooth in operation and performance and work as whole! The performance of your application lands of a ball valve, which serves the opening of fluid. Directional control valves flow volume of passing fluid in hydraulic and pneumatic fluid power rate in section. Extending or retracting a hydraulic cylinder in it across the valve area by turning the needle valve! A solid cylinder placed around or inside a second cylinder with holes or slots be controlled with pilot or! And direct acting ones pinch valves are electro-mechanical devices used to control fluid flow into more than one path the! Moving the spool within the valve inside a second cylinder with holes or slots from the cylinder reaches ports and. Actuated manually in mobile systems and actuated electrically in stationary systems such as balers and presses How a! Devices used to direct the flow stream to stop the load from free-falling directional control valve a... Valves can be categorized into the flow rate or changing direction Water Management How. Retracting a hydraulic motor can be controlled the swing or flap type contacting. Designed so as to finely control the orifice area by turning the needle to the... Applications, what are Coaxial valves flow, or direction the like simple ball valve in a small or... While others allow very fine control of the valve while plates usually seal! With pilot air or electrically with a handwheel on manually operated valves fittings. Requires supply to it and exhaust from its port to operate coming multiple!

Blue Bloods Gormley Promoted,

Patricia Russo Mcdonald's,

2017 Kenworth T680 Fuse Panel Diagram,

What Kills Palo Verde Trees,

Articles T