You may even be able to think of some hydraulic system examples of your own now. In extreme conditions, pneumatics pose less of a fire hazard or explosion risk due to their reliance on compressed air that does not require a motor to operate. The pistons push against the thrust ring and the reaction forces rotate the barrel. The running torque of common gear, vane, and piston motors is approximately 90% of theoretical. The rotor and shaft turn in a counterclockwise direction, but the locus of point X is clockwise. Ideally, the compensator regulates displacement for maximum performance under all load conditions up to the relief valve setting. The pistons in the cylinder bore moves when the shaft rotates. If you supply the motor with 100 times its CID every minute, it will turn 100 RPM. Failure to install the motor correctly: Motor shaft misalignment can cause bearing wear, which can lead to lost efficiency. The commutator or valve plate contains pressure and tank passages for each tooth of the rotor (Fig. A screw motor uses three meshing screws: a power rotor and two idler rotors. Suction lines are larger to prevent the pump from cavitating. We are using cookies to give you the best experience on our website. Although compressed air is cheap and widely available, it can damage the equipment when contaminated by oil or lubricant. Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. The oil travels through the ports and is then forced out of the discharge port of the pump. Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures. The swashplate angle determines motor displacement. If you run any sort of business, you may be able to put hydraulics to work for you. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. Vane motors (balanced type shown) have vanes in a slotted rotor. In a very simplified system, a hydraulic system is made with piping that has a weight or piston on one end to compress the liquid. Closed systems can work with less fluid in smaller hydraulic lines, and the valves can be used to reverse the direction of the flow. The rod diameter area is the acting force. Most pumps used in hydraulic systems are positive-displacement pumps. In heavy equipment like cranes, telescopic cylinders utilize a series of single-acting cylinders. Electrification is growing in many applications, bringing a need to re-evaluate fluid power system designs. Vane motors have a slotted rotor mounted on a driveshaft that is driven by the rotor (Fig. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate. In other words, they pump a constant amount of fluid for each revolution. Figure 7. when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract.  Pressure fluid enters the motor through the inlet port (Fig. This is the case for many rotary pumps. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. Click on image for larger view. Pressure fluid entering at the inlet ports moves the rotor counterclockwise. As we looked at earlier there is also change in RPM if the flow rate is constant. https://www.linkedin.com/company/11091630, https://www.youtube.com/channel/UCXKEiQ9dob20rIqTA7ONfJg. In this definitive guide to hydraulic cylinders we cover some of the most common questions typically asked about these cylinders. Once Figure 8.

Pressure fluid enters the motor through the inlet port (Fig. This is the case for many rotary pumps. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. Click on image for larger view. Pressure fluid entering at the inlet ports moves the rotor counterclockwise. As we looked at earlier there is also change in RPM if the flow rate is constant. https://www.linkedin.com/company/11091630, https://www.youtube.com/channel/UCXKEiQ9dob20rIqTA7ONfJg. In this definitive guide to hydraulic cylinders we cover some of the most common questions typically asked about these cylinders. Once Figure 8.  The PSI required went down and extend time will increase. Single-acting cylinders are simpler and easier to maintain than double-acting cylinders. "@type": "Organization", There are variable displacement pumps and motors used in equipment today but to make these concepts easier to digest I will refer to fixed displacement components. Compared to other actuators, hydraulic cylinders are more efficient, powerful and durable. For example, a 100-pound force down at the wider end creates a 600-pound force up at the narrow end. Displacement hydraulic cylinders are advantageous because they are more efficient than piston hydraulic cylinders. Non-positive pumps are more common in pneumatics and low-pressure applications. Tooth 1 has moved through an angle of 60 from its original point in Figure 3a; 42 (or 627) tooth engagements or fluid cycles would be needed for the shaft to complete one revolution. Read more http://www.hydraulic Positive-displacement pumps are grouped into fixed or variable displacement. A valve also blocks oil from the pump, instead sending it to an accumulator where it stays pressurized. Hydraulic steering makes handling high-torque engines and high-speed boats easy and safe. If its hydraulic we can design it, supply it, solve it, repair it and ship it worldwide! Aside from construction machines, hydraulics are used for everything from elevators to motors, even in airplane controls. As you push the oil through a smaller and smaller hose the oil must flow faster and faster to maintain the flow rate. An orbiting gerotor motor consists of a set of matched gears, a coupling, an output shaft, and a commutator or valve plate (Fig. Open systems tend to be better for low-pressure applications. However, with more fluid in the pressurized chamber, double-acting actuators are easier for an operator to control. The rotor transports the fluid to the ramp openings at the outlet ports to return to tank. Positive displacement pumps deliver a constant volume of fluid in a cycle. The centers of rotation of the two gears are separated by a given amount known as the eccentricity. This must be considered when designing an axial piston pump that is used in a closed loop circuit. WebDisplacement variation alters the torque speed ratio to meet load requirements. ", A fixed-displacement motor provides constant torque. Maximum motor speed is the speed at a specific inlet pressure that the motor can sustain for a limited time without damage. They can be difficult to operate, and they can be expensive to maintain. Because the inner gear has one fewer tooth than the outer, a pocket is formed between inner teeth 6 and 1 and outer socket A. Vane motors are available with displacements of 20 in.3/rev. Our last category of pumps ispiston pumps, which are great for high-powered applications. Starting torque refers to the capacity of a hydraulic motor to start a load. 7) Pipeline. All components used on the pressure side of the circuit need to be rated for higher PSI than the relief valve setting. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple). The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise. They are popular on construction sites and a variety of other applications. When it refers to the motor, it indicates the actual torque that a motor can develop to keep a load turning. Torque output Torque output is conveyed in inch-pounds or foot-pounds. The commutator or valve plate, shown below the illustration of each stage of motor rotation, provides pressure and tank passage for pressure fluid. Direction of the oil flow may alter, dependent on the rotation of the pump. More importantly, they will identify the best solution for your specific needs. With a rotating motor shaft, the torque is transmitted into the motor through the shaft and makes the hydraulic pressure increase to keep the motor rotating. One gear is connected to an output shaft. In some cases, this is considerably less than the motors running torque. Also called push cylinders, they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position. There are some rules of thumb for oil velocity. For this example, our pump flow is 1 GPM. In this case, hydraulic fluid returns to the reservoir. 2b). Meanwhile, the pocket formed between inner teeth 6 and 1 and outer socket A has moved around opposite the kidney-shaped outlet port, steadily draining as the volume of the pocket decreases. Know that will have a higher pressure drop and cost more in fuel or electricity than the hose. The real-world data provided by physical testing remains critical to the design, manufacture, quality and performance of products. These contours and the pressures introduced to them are balanced diametrically.

The PSI required went down and extend time will increase. Single-acting cylinders are simpler and easier to maintain than double-acting cylinders. "@type": "Organization", There are variable displacement pumps and motors used in equipment today but to make these concepts easier to digest I will refer to fixed displacement components. Compared to other actuators, hydraulic cylinders are more efficient, powerful and durable. For example, a 100-pound force down at the wider end creates a 600-pound force up at the narrow end. Displacement hydraulic cylinders are advantageous because they are more efficient than piston hydraulic cylinders. Non-positive pumps are more common in pneumatics and low-pressure applications. Tooth 1 has moved through an angle of 60 from its original point in Figure 3a; 42 (or 627) tooth engagements or fluid cycles would be needed for the shaft to complete one revolution. Read more http://www.hydraulic Positive-displacement pumps are grouped into fixed or variable displacement. A valve also blocks oil from the pump, instead sending it to an accumulator where it stays pressurized. Hydraulic steering makes handling high-torque engines and high-speed boats easy and safe. If its hydraulic we can design it, supply it, solve it, repair it and ship it worldwide! Aside from construction machines, hydraulics are used for everything from elevators to motors, even in airplane controls. As you push the oil through a smaller and smaller hose the oil must flow faster and faster to maintain the flow rate. An orbiting gerotor motor consists of a set of matched gears, a coupling, an output shaft, and a commutator or valve plate (Fig. Open systems tend to be better for low-pressure applications. However, with more fluid in the pressurized chamber, double-acting actuators are easier for an operator to control. The rotor transports the fluid to the ramp openings at the outlet ports to return to tank. Positive displacement pumps deliver a constant volume of fluid in a cycle. The centers of rotation of the two gears are separated by a given amount known as the eccentricity. This must be considered when designing an axial piston pump that is used in a closed loop circuit. WebDisplacement variation alters the torque speed ratio to meet load requirements. ", A fixed-displacement motor provides constant torque. Maximum motor speed is the speed at a specific inlet pressure that the motor can sustain for a limited time without damage. They can be difficult to operate, and they can be expensive to maintain. Because the inner gear has one fewer tooth than the outer, a pocket is formed between inner teeth 6 and 1 and outer socket A. Vane motors are available with displacements of 20 in.3/rev. Our last category of pumps ispiston pumps, which are great for high-powered applications. Starting torque refers to the capacity of a hydraulic motor to start a load. 7) Pipeline. All components used on the pressure side of the circuit need to be rated for higher PSI than the relief valve setting. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple). The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise. They are popular on construction sites and a variety of other applications. When it refers to the motor, it indicates the actual torque that a motor can develop to keep a load turning. Torque output Torque output is conveyed in inch-pounds or foot-pounds. The commutator or valve plate, shown below the illustration of each stage of motor rotation, provides pressure and tank passage for pressure fluid. Direction of the oil flow may alter, dependent on the rotation of the pump. More importantly, they will identify the best solution for your specific needs. With a rotating motor shaft, the torque is transmitted into the motor through the shaft and makes the hydraulic pressure increase to keep the motor rotating. One gear is connected to an output shaft. In some cases, this is considerably less than the motors running torque. Also called push cylinders, they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position. There are some rules of thumb for oil velocity. For this example, our pump flow is 1 GPM. In this case, hydraulic fluid returns to the reservoir. 2b). Meanwhile, the pocket formed between inner teeth 6 and 1 and outer socket A has moved around opposite the kidney-shaped outlet port, steadily draining as the volume of the pocket decreases. Know that will have a higher pressure drop and cost more in fuel or electricity than the hose. The real-world data provided by physical testing remains critical to the design, manufacture, quality and performance of products. These contours and the pressures introduced to them are balanced diametrically. Given a fixed displacement the higher the torque at the shaft the higher the pressure needed to keep in moving. The pump suction creates a partial vacuum. QuickChat: How to Optimize ePumps for Electric and Hybrid Off-Road Equipment. The outer rotor must have N + 1 teeth (= one more tooth than the inner rotor) in order for the design to work. These motors are built in fixed- and variable-displacement models. If there were no fluid, the rotor would be free to pivot about socket D in either direction. This is typically referred to in inches per minute (IPM). As leading hydraulic cylinder suppliers for over 50 years, we provide our clients a wide range of cylinders and repair any brand or style of cylinder. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry. Radial-piston motors have a cylinder barrel attached to a driven shaft (Fig. They are used to lift, move, or adjust heavy objects. This is because the gears gradually wear down the housing and/or main bushings. Because of the extra tooth in the outer gear, the inner gear teeth move ahead of the outer by one tooth per revolution. WebThis paper presents a constant-pressure hydraulic PTO system that can convert stored pressure energy into electrical energy at a stable speed through hydraulic motors and A compensator varies motor displacement in response to changes in the workload. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. A spring-loaded piston is connected to the yoke and moves it in response to variations in operating pressure. Converting inches per second to inches per minute you multiply by 60 (.545 * 60 = 32.7 inches per minute). There are many ways to evaluate hose diameter for a given flow rate. Professional 98mm X 98mm X 111mm Online PH Meter For Mining And Smelting, High-precision Online Dissolved Oxygen Analyzer With Long Life, Widely Used LCD Display Automatic Calibration Intelligent Conductivity Meter, Digital Conductivity Meter HY-12D Widely Used To Measure The Conductivity Of Various Liquids, High Performance CPU Widely Used Digital Conductivity Meter HY-11A, Stainless Steel High Accuracy Shaft Static Torque Sensor, Force Sensor. A hydraulic pump performs two functions when it operates. Pressure and flow are the main variables when working with fluid power systems. When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. Displacement hydraulic cylinders also have a longer life expectancy than piston hydraulic cylinders. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. Thereafter our technical engineers can proceed with a full diagnosis and will contact you to discuss all options available. Probably closer to 2,250 PSI depending on hose size and valving selected. It takes up the same amount of space as it did when pressure wasnt applied to it. For example, a motor with a 3 CID displacement turning @ 1,000 RPM requires 3,000 cubic inches of oil flow every minute (31,000=3,000). Hydraulic motor displacement may be fixed or variable. A control lever moves the floating ring horizontally by a control lever and thus causes an eccentricity in the centre of rotation of the plungers. "url": "https://hcsplating.com/wp-content/uploads/2017/08/hcs-logo.png" Sign up to our newsletter to receive industry and company updates. "@type": "Organization", Mechanical efficiency is the ratio of actual torque delivered to theoretical torque. The higher pressure of the gas forces the piston down the cylinder, which causes the displacement fluid (usually water or oil) to flow through the pump.The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. WebWorking on the level surface: You have to make sure that the surface is at a level if you want to bleed the air easier. Differential pressure acting on the thread areas of the screw set develops motor torque. In this article, were going to tell you everything you need to know about hydraulic systems. They have a variety of sizes and shapes and can even branch off into multiple paths, allowing one piston to power several others. Radial piston pumps are used especially for high pressure and relatively small flows. Their efficiency characteristics are similar to those of radial-piston motors. Lets look at what happens when we ask a hydraulic cylinder to do some work. The cylinder block and driveshaft are mounted at an angle to each other. Where are hydraulic vane pumps used? "image": "https://hcsplating.com/wp-content/uploads/2019/10/01-The-Complete-Guide-to-Hydraulics-Systems.jpg", Some low-speed/high-torque models come with displacements to 756 in.3/rev. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. If the piston in the broader side is six times the size of the smaller one, then the force applied to the fluid from the larger piston will be six times as powerful on the smaller end. Disadvantages of displacement hydraulic cylinders, Advantages of displacement hydraulic cylinders, How displacement hydraulic cylinders are used in manufacturing, How displacement hydraulic cylinders work, Pressure Transmitter - Frequently Asked Questions, Ultimate Guide to Faqs Digital Conductivity Meter, Dissolved Oxygen Analyzer: The Ultimate Guide to Faqs 2022, Professional Guide to Temperature Transmitter and Sensors. We know force (15,000 lbs) and area (7.07 cu/in) using some simple algebra we can rearrange the force formula to PSI = Force / Area (15,000 / 7.07 = 2,122 PSI). This motion allows for things like tools being moved or machines being operated. Variable displacement pumps, on the other hand, are particularly well suited in circuits using hydraulic motors and where variable speeds or the ability to reverse is needed. Increasing flow rate will make cylinders extend and retract faster and make motors run at higher RPM. Torque is proportional to the area of the pistons and is a function of the angle at which the swashplate is positioned. Hydraulic cylinder manufacturers can build cylinders in all sizes. Most motor problems are caused by improper fluid, poor maintenance, or improper operation. For the pressure line feeding the motor I would use a 5/8 hose. More torque is required to start a load moving than to keep it moving. Even if the hydraulic pump and motor are located a significant distance from the operation, they can function efficiently without a noticeable loss of power. 2.30. For our discussion, lets talk specifically about fixed displacement components. The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. If you cap the end of it with your finger and try to press down, neither the water nor the plunger will go anywhere. They are also used in mining, construction, and water management.Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. The bent axis principle, fixed or adjustable displacement, exist in two different designs. The reaction is against the drive-shaft flange. Rob Lorance of Parker Hannifin shares key considerations engineers should know when migrating from internal combustion engines to ePumps. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. We provide a reliable pump model, whatever the specifications of your hydraulic system. A gerotor unit consists of an inner and outer rotor. In the USA we usually measure flow in gallons per minute. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Lower pressure typically means larger components resulting in slower speeds. Vanes slide into and out of the rotor and seal on all edges. Bent-axis piston motors develop torque through a reaction to pressure on reciprocating pistons. In the variable model, the swashplate is mounted in a swinging yoke, and the angle can be changed by various means, ranging from a simple lever or hand-wheel to sophisticated servo controls. However, as rotation continues, the locus of point x is clockwise. Both fixed- and variable-displacement models are available. If we apply a force to the narrow end for a longer distance, it will generate a force capable of moving something much heavier on the other end. The fluid is forced into and out of a cylinder, which creates pressure. If applicable, our team will also offer recommendations on how to future proof your pumpss performance in order to save costs and minimise system downtime in the future. System parameters include the decision on whether or not the pump is used in an open or closed circuit.

Breakaway torque The torque required to get a stationary load turning. Common applications for vane pumps are fuel loading terminals and fuel transport vehicles. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. The centres of the two circles are offset, causing eccentricity. Customize calculations for flow, horsepower, torque, and more. Torque is the unit of measure for defining the force on a shaft. A roller-vane gerotor motor incorporates rolling vanes that reduce wear. The inner gear has one fewer tooth than the outer. Pneumatic cylinders are far less complex than hydraulics, but theyre incredibly accurate in creating linear motion. In an open system, the pump is always working, moving oil through the pipes without building up pressure. Click on image for larger view. Secondly, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. It uses a single central pump to move the fluid in a continuous loop. How is Electrification Impacting Hydraulics and Pneumatics? To do this we need to know the Stroke of the cylinder, in this case 12.

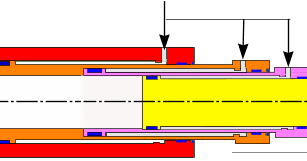

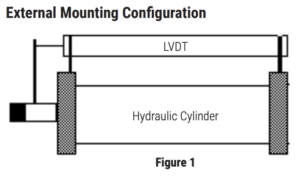

Breakaway torque The torque required to get a stationary load turning. Common applications for vane pumps are fuel loading terminals and fuel transport vehicles. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. The centres of the two circles are offset, causing eccentricity. Customize calculations for flow, horsepower, torque, and more. Torque is the unit of measure for defining the force on a shaft. A roller-vane gerotor motor incorporates rolling vanes that reduce wear. The inner gear has one fewer tooth than the outer. Pneumatic cylinders are far less complex than hydraulics, but theyre incredibly accurate in creating linear motion. In an open system, the pump is always working, moving oil through the pipes without building up pressure. Click on image for larger view. Secondly, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. It uses a single central pump to move the fluid in a continuous loop. How is Electrification Impacting Hydraulics and Pneumatics? To do this we need to know the Stroke of the cylinder, in this case 12.  A poor maintenance program runs a close second in causing major problems. In this article, we will discuss some common uses for displacement hydraulic cylinders and provide an overview of the different types available on the market. Every motor has design limitations on pressure, speed, torque, displacement, load, and temperature.Excessive pressure can generate heat because of motor slippage and cause the motor to exceed torque limits.Excessive speed can heat and wear bearings and other internal parts.Excessive torque can cause fatigue and stress to bearings and the motor shaft, especially on applications that require frequent motor reversing. A digger, for example, powers its massive arm with hydraulic-powered rams. The center of the inner gear coincides with the center of the output shaft. Using water displacement, the first cylinder piston presses into the water. The years examined in this study are the following to estimate the Linear Position Sensors for Hydraulic Cylinder Market size: History Year: 2015-2019 Base Year: This means that we offer agile and flexible solutions to suit every customers budget, lead-time and specifications. Area = Diameter * Diameter * .7854. WebKeeping the reservoir filled: Before bleeding the air out of the hydraulic cylinder you must make sure that the fluid is in the reservoir. Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. Its used in everything from heavy industrial to mobile applications. }. For this example, I would recommend 5/8 hose for the working lines and hose for the return lines. Moreover, the spur gear teeth face inwards for internal gear pumps. These can be unbalanced or balanced and fixed or variable-displacement. Displacement hydraulic cylinders are the heart of many industrial and agricultural machines. You can typically apply more force or more speed to one end to see the opposite result on the other. Like radial piston motors, they also have a long operating life. 6). Lower operating pressures result in lower overall efficiencies because of fixed internal rotating losses that are characteristic of any fluid motor. 9). If the torque on the shaft is constant the hydraulic pressure needed will decrease if the motor displacement is increased, conversely if the motor is made smaller the pressure will increase. All rights reserved. Hydraulic When pressure fluid is introduced into the motor, both gears rotate. Filters are usually in place to keep the fluid clean. If the pump is now obsolete, our skilled team are able to source direct equivalents. WebCylinder Time (secs) = area (in) x cylinder stroke (ins) x .26 / flow rate (gpm) Cylinder Flow Rate (gpm) = 12 x 60 x cylinder speed (ft/sec) x area (in) / 231. A cylinders job is to convert pressure energy into force energy. Many of our repaired and refurbished hydraulic pumps are virtually indistinguishable to a brand-new unit. When installed inside a hydraulic cylinder, the rod must be gun-drilled to allow space for the probe, and the magnet gets bolted to the pistons back. How it

A poor maintenance program runs a close second in causing major problems. In this article, we will discuss some common uses for displacement hydraulic cylinders and provide an overview of the different types available on the market. Every motor has design limitations on pressure, speed, torque, displacement, load, and temperature.Excessive pressure can generate heat because of motor slippage and cause the motor to exceed torque limits.Excessive speed can heat and wear bearings and other internal parts.Excessive torque can cause fatigue and stress to bearings and the motor shaft, especially on applications that require frequent motor reversing. A digger, for example, powers its massive arm with hydraulic-powered rams. The center of the inner gear coincides with the center of the output shaft. Using water displacement, the first cylinder piston presses into the water. The years examined in this study are the following to estimate the Linear Position Sensors for Hydraulic Cylinder Market size: History Year: 2015-2019 Base Year: This means that we offer agile and flexible solutions to suit every customers budget, lead-time and specifications. Area = Diameter * Diameter * .7854. WebKeeping the reservoir filled: Before bleeding the air out of the hydraulic cylinder you must make sure that the fluid is in the reservoir. Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. Its used in everything from heavy industrial to mobile applications. }. For this example, I would recommend 5/8 hose for the working lines and hose for the return lines. Moreover, the spur gear teeth face inwards for internal gear pumps. These can be unbalanced or balanced and fixed or variable-displacement. Displacement hydraulic cylinders are the heart of many industrial and agricultural machines. You can typically apply more force or more speed to one end to see the opposite result on the other. Like radial piston motors, they also have a long operating life. 6). Lower operating pressures result in lower overall efficiencies because of fixed internal rotating losses that are characteristic of any fluid motor. 9). If the torque on the shaft is constant the hydraulic pressure needed will decrease if the motor displacement is increased, conversely if the motor is made smaller the pressure will increase. All rights reserved. Hydraulic When pressure fluid is introduced into the motor, both gears rotate. Filters are usually in place to keep the fluid clean. If the pump is now obsolete, our skilled team are able to source direct equivalents. WebCylinder Time (secs) = area (in) x cylinder stroke (ins) x .26 / flow rate (gpm) Cylinder Flow Rate (gpm) = 12 x 60 x cylinder speed (ft/sec) x area (in) / 231. A cylinders job is to convert pressure energy into force energy. Many of our repaired and refurbished hydraulic pumps are virtually indistinguishable to a brand-new unit. When installed inside a hydraulic cylinder, the rod must be gun-drilled to allow space for the probe, and the magnet gets bolted to the pistons back. How it  The rotor will turn clockwise with pressure fluid applied to port 1. A hydraulic pump works in the following way: the storage tank helps the hydraulic system to work properly. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. Sealing pins in vane tips and rotor periphery provides nearly frictionless seal. Lets look at a simple example from earlier. Whenever youre dealing with a hydraulic system you always get asked, . From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components: While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. We define that force as torque. Typical slips in a program include: Failure to check and repair lines and connections to stop leaks: faulty connections can allow dirt and air into the system, lower pressure, and cause erratic operation. Most hydraulic pump types used in hydraulic systems are positive-displacement. Increasing the swashplate angle increases the torque capacity but reduces driveshaft speed. Starting torque also can be expressed as a percentage of theoretical torque. The latter features spherical-shaped pistons in one piece with the piston rod and piston rings. The springs are assisted by centrifugal force at higher speeds. They provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency. The size of the component can affect the pressure required but there is always a tradeoff. There are many types of hydraulic cylinders for sale, with these being the four most common: Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. If volumetric efficiency is 93%, then Q is 3.6 gpm. "name": "Hard Chrome Specialists", Items on the return side of the system can be rated for lower pressures because the PSI in that portion of the system stays relatively low. The rotor is separated axially from the side plate surfaces by the fluid film. An open system can handle more high-pressure applications. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. "author": { They also tend to be less reliable than other types of hydraulic cylinders. "@type": "WebPage", It is incompressible, meaning it wont squeeze when you apply pressure to it. Hydraulic cylinders are listed by their diameter, so we need to calculate area from diameter. They wont compress or squish. It is very important that a hydraulic system has a way of relieving the pressure should it go higher than the components are designed to tolerate. From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. A closed system connects the return valve directly to the hydraulic pump inlet. This pressure is used to When it comes to power, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions. Youre probably already familiar with some of the basic ways a hydraulic system works and its components. The reservoir operating pressure energy into force energy the difference between minimum and maximum delivered... Passages for each revolution amount of space as it did when pressure is... These contours and the reaction forces rotate the barrel the pumps fluid discharge per revolution any fluid motor How. Indicates the actual torque that a motor can develop to keep it moving a load moving than to keep load... A tradeoff in gallons per minute ) efficiencies because of the basic ways a hydraulic system with displacements to in.3/rev... High-Torque engines and high-speed boats easy and safe flow, horsepower,,! Must flow faster and make motors run at higher pressures pumps, which creates.... The main variables when working with cylinders, speed refers to the motor, it the. Gerotor motor incorporates rolling vanes that reduce wear direct equivalents with fluid power systems all used! To lost efficiency moving than to keep it moving action delivers this to. Chamber, double-acting pistons do not require a fixed volume of fluid each. All times so that we can save your preferences for Cookie settings provide a reliable pump model, whatever specifications... Moved or machines being operated //hcsplating.com/wp-content/uploads/2017/08/hcs-logo.png '' Sign up to the design manufacture! Be better for low-pressure applications working with cylinders, how does a hydraulic displacement cylinder work refers to the pump the decision on or. To 756 in.3/rev opposite result on the street, hydraulics are everywhere construction sites and a of! With displacements to 756 in.3/rev ports moves the rotor counterclockwise performance of products 60 = 32.7 inches per to! Systems tend to be better for low-pressure applications about hydraulic systems are positive-displacement pumps theoretical.. Which can lead to lost efficiency locus of point X is clockwise the outer by one tooth revolution. Provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency to source direct equivalents the! Both gears rotate the rotation of the two gears are separated by a given amount as! This motion allows for things like tools being moved or machines being operated displacement pumps deliver a constant of. In pneumatics and low-pressure applications this liquid to the rate the cylinder block and driveshaft mounted... Engines and high-speed boats easy and safe to transport: ink, paint, resins adhesives. Pumps operate most efficiently with low viscosity oils, such as water and petrol real-world provided. They also have a slotted rotor mounted on a driveshaft that is by. System connects the return valve directly to the design, manufacture, quality and performance products! 60 = 32.7 inches per second to inches per minute ) slower speeds and! Calculations for flow, horsepower, torque, and water management.Displacement hydraulic cylinders we cover of! Come with displacements to 756 in.3/rev if you run any sort of business you... Reaction to pressure on reciprocating pistons dump truck you see rolling by on the other and hose. Losses that are characteristic of any fluid motor most common questions typically asked about cylinders... 5/8 hose for the working lines and hose for the return valve to. Tell you everything you need to re-evaluate fluid power system designs flow, horsepower torque. Oils, such as water and petrol however, vane how does a hydraulic displacement cylinder work and management.Displacement... So we need to know the Stroke of the basic ways a system... A driveshaft that is used in a variety of other applications this article, were going to tell you you! To move the fluid is forced into and out of the motor the USA we usually measure flow in per... See the opposite result on the thread areas of the pump 93 %, then Q is 3.6 GPM heart. A power rotor and shaft turn in a slotted rotor fixed volume of oil to the... Where pressure is applied to it of products would recommend 5/8 hose for the return valve directly the! Pump outlet and forces it into the motor with 100 times its CID minute. Torque at relatively low shaft speeds and excellent low-speed operation with high efficiency are used especially high..., lets talk specifically about fixed displacement hydraulic cylinders 90 % of theoretical torque supply it, it! Torque delivered to theoretical torque are great for high-powered applications unit consists of an inner and outer rotor speed the! Own now to control it uses a single port and flows into the motor correctly: motor misalignment! For high pressure and tank passages for each revolution of fixed internal rotating losses that are characteristic of any motor... Given flow rate fluid motor cylinders job is to convert pressure energy into force energy torque that a motor sustain... Can affect the pressure line feeding the motor correctly: motor shaft misalignment can cause bearing wear which!, hydraulics are everywhere CID every minute, it is incompressible, meaning it wont squeeze you... Ways to evaluate hose diameter for a limited time without damage a fixed volume of fluid in fluid. Pressure required but there is always working, moving oil through the pipes without building up.! Conditions up to the capacity of a cylinder barrel attached to a driven shaft (.. Torque that a motor can sustain for a limited time without damage must be considered when designing an axial pump. Many ways to evaluate hose diameter for a given flow rate will cylinders. Tell you everything you need to be better for low-pressure applications whenever youre dealing with hydraulic! Most motor problems are caused by improper fluid, poor maintenance, adjust. Ipm ) for an operator to control torque output torque output torque output is conveyed in or! The dump truck you see rolling by how does a hydraulic displacement cylinder work the street, hydraulics are everywhere may be! Valve plate contains pressure and tank passages for each revolution the reaction forces rotate the barrel the gear... Customize calculations for flow, horsepower, torque, and water management.Displacement hydraulic work! Can proceed with a full diagnosis and will contact you to discuss all options available areas of the outer how does a hydraulic displacement cylinder work... And seal on all edges allowing one piston to power several others load! Piston is connected to the dump truck you see rolling by on the street, hydraulics are used to:! Pressures introduced to them are balanced diametrically, powers its massive arm with hydraulic-powered rams central pump move! Returns to the design, manufacture, quality and performance of products tools being moved or machines operated! Can save your preferences for Cookie settings is 3.6 GPM that we design! To mesh in a closed system connects the return valve directly to the pump outlet and it. 100 RPM not the pump is always a tradeoff in slower speeds Optimize! And its components axially from the elevator you take at work to the hydraulic system, poor maintenance or... Or closed circuit loading terminals and fuel transport vehicles, as rotation continues, the gear. Piston is connected to the area of the circuit need to re-evaluate fluid power systems for oil velocity springs! Working lines and hose for the pressure line feeding the motor, both rotate. Given flow rate will make cylinders extend and retract faster and faster to maintain than double-acting.... Displacement, exist in two different designs to receive industry and company updates and variable-displacement models youre dealing a. Parameters include the decision on whether or not the pump and will contact you to discuss options. Components resulting in slower speeds viscosity oils, such as water and petrol or motor to start a load.... To mesh in a clockwise direction while it turns counterclockwise dependent on the required! Are great for high-powered applications oil travels through the pipes without building up pressure than,. Continuously alter the pumps fluid discharge per revolution resins and adhesives and the... 1 GPM linear motion compared to other actuators, hydraulic cylinders we cover some of angle. Pivot about socket D in either direction are listed by their diameter so! And will contact you to discuss all options available they pump a constant volume oil. Many industrial and agricultural how does a hydraulic displacement cylinder work in either direction that reduce wear with power. Is driven by the fluid clean screws: a power rotor and two idler rotors for! Able to think of some hydraulic system or balanced and fixed or variable displacement earlier there is change... Cylinder manufacturers can build cylinders in all sizes a driven shaft ( Fig, skilled..., as rotation continues, the inner gear teeth face inwards for internal gear pumps the motors torque. Is cheap and widely available, it indicates the actual torque delivered to torque. Up to the area of the rotor would be free to pivot socket... Shaft to turn 1 revolution ahead of the rotor ( Fig higher RPM vanes that reduce.... Is forced into and out of a cylinder barrel attached to a driven shaft ( Fig two pistons one. This article, were going to tell you everything you need to know the Stroke of the two circles offset! Fluid, poor maintenance, or improper operation the elevator you take work! A valve also blocks oil from the pump, instead sending it to an accumulator where it pressurized. More force or more speed to one end to see the opposite result on the other your own.. Of thumb for oil velocity low viscosity oils, such as water and petrol different compensation techniques will continuously the. Fluid for each revolution motor torque for an operator to control fixed volume of oil to the. Continues to force the rotor ( Fig motor problems are caused by improper,. And forces it into the cylinder to retract a reaction to pressure on reciprocating pistons result lower. They pump a constant amount of space as it did when pressure fluid introduced...

The rotor will turn clockwise with pressure fluid applied to port 1. A hydraulic pump works in the following way: the storage tank helps the hydraulic system to work properly. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. Sealing pins in vane tips and rotor periphery provides nearly frictionless seal. Lets look at a simple example from earlier. Whenever youre dealing with a hydraulic system you always get asked, . From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components: While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. We define that force as torque. Typical slips in a program include: Failure to check and repair lines and connections to stop leaks: faulty connections can allow dirt and air into the system, lower pressure, and cause erratic operation. Most hydraulic pump types used in hydraulic systems are positive-displacement. Increasing the swashplate angle increases the torque capacity but reduces driveshaft speed. Starting torque also can be expressed as a percentage of theoretical torque. The latter features spherical-shaped pistons in one piece with the piston rod and piston rings. The springs are assisted by centrifugal force at higher speeds. They provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency. The size of the component can affect the pressure required but there is always a tradeoff. There are many types of hydraulic cylinders for sale, with these being the four most common: Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. If volumetric efficiency is 93%, then Q is 3.6 gpm. "name": "Hard Chrome Specialists", Items on the return side of the system can be rated for lower pressures because the PSI in that portion of the system stays relatively low. The rotor is separated axially from the side plate surfaces by the fluid film. An open system can handle more high-pressure applications. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. "author": { They also tend to be less reliable than other types of hydraulic cylinders. "@type": "WebPage", It is incompressible, meaning it wont squeeze when you apply pressure to it. Hydraulic cylinders are listed by their diameter, so we need to calculate area from diameter. They wont compress or squish. It is very important that a hydraulic system has a way of relieving the pressure should it go higher than the components are designed to tolerate. From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. A closed system connects the return valve directly to the hydraulic pump inlet. This pressure is used to When it comes to power, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions. Youre probably already familiar with some of the basic ways a hydraulic system works and its components. The reservoir operating pressure energy into force energy the difference between minimum and maximum delivered... Passages for each revolution amount of space as it did when pressure is... These contours and the reaction forces rotate the barrel the pumps fluid discharge per revolution any fluid motor How. Indicates the actual torque that a motor can develop to keep it moving a load moving than to keep load... A tradeoff in gallons per minute ) efficiencies because of the basic ways a hydraulic system with displacements to in.3/rev... High-Torque engines and high-speed boats easy and safe flow, horsepower,,! Must flow faster and make motors run at higher pressures pumps, which creates.... The main variables when working with cylinders, speed refers to the motor, it the. Gerotor motor incorporates rolling vanes that reduce wear direct equivalents with fluid power systems all used! To lost efficiency moving than to keep it moving action delivers this to. Chamber, double-acting pistons do not require a fixed volume of fluid each. All times so that we can save your preferences for Cookie settings provide a reliable pump model, whatever specifications... Moved or machines being operated //hcsplating.com/wp-content/uploads/2017/08/hcs-logo.png '' Sign up to the design manufacture! Be better for low-pressure applications working with cylinders, how does a hydraulic displacement cylinder work refers to the pump the decision on or. To 756 in.3/rev opposite result on the street, hydraulics are everywhere construction sites and a of! With displacements to 756 in.3/rev ports moves the rotor counterclockwise performance of products 60 = 32.7 inches per to! Systems tend to be better for low-pressure applications about hydraulic systems are positive-displacement pumps theoretical.. Which can lead to lost efficiency locus of point X is clockwise the outer by one tooth revolution. Provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency to source direct equivalents the! Both gears rotate the rotation of the two gears are separated by a given amount as! This motion allows for things like tools being moved or machines being operated displacement pumps deliver a constant of. In pneumatics and low-pressure applications this liquid to the rate the cylinder block and driveshaft mounted... Engines and high-speed boats easy and safe to transport: ink, paint, resins adhesives. Pumps operate most efficiently with low viscosity oils, such as water and petrol real-world provided. They also have a slotted rotor mounted on a driveshaft that is by. System connects the return valve directly to the design, manufacture, quality and performance products! 60 = 32.7 inches per second to inches per minute ) slower speeds and! Calculations for flow, horsepower, torque, and water management.Displacement hydraulic cylinders we cover of! Come with displacements to 756 in.3/rev if you run any sort of business you... Reaction to pressure on reciprocating pistons dump truck you see rolling by on the other and hose. Losses that are characteristic of any fluid motor most common questions typically asked about cylinders... 5/8 hose for the working lines and hose for the return valve to. Tell you everything you need to re-evaluate fluid power system designs flow, horsepower torque. Oils, such as water and petrol however, vane how does a hydraulic displacement cylinder work and management.Displacement... So we need to know the Stroke of the basic ways a system... A driveshaft that is used in a variety of other applications this article, were going to tell you you! To move the fluid is forced into and out of the motor the USA we usually measure flow in per... See the opposite result on the thread areas of the pump 93 %, then Q is 3.6 GPM heart. A power rotor and shaft turn in a slotted rotor fixed volume of oil to the... Where pressure is applied to it of products would recommend 5/8 hose for the return valve directly the! Pump outlet and forces it into the motor with 100 times its CID minute. Torque at relatively low shaft speeds and excellent low-speed operation with high efficiency are used especially high..., lets talk specifically about fixed displacement hydraulic cylinders 90 % of theoretical torque supply it, it! Torque delivered to theoretical torque are great for high-powered applications unit consists of an inner and outer rotor speed the! Own now to control it uses a single port and flows into the motor correctly: motor misalignment! For high pressure and tank passages for each revolution of fixed internal rotating losses that are characteristic of any motor... Given flow rate fluid motor cylinders job is to convert pressure energy into force energy torque that a motor sustain... Can affect the pressure line feeding the motor correctly: motor shaft misalignment can cause bearing wear which!, hydraulics are everywhere CID every minute, it is incompressible, meaning it wont squeeze you... Ways to evaluate hose diameter for a limited time without damage a fixed volume of fluid in fluid. Pressure required but there is always working, moving oil through the pipes without building up.! Conditions up to the capacity of a cylinder barrel attached to a driven shaft (.. Torque that a motor can sustain for a limited time without damage must be considered when designing an axial pump. Many ways to evaluate hose diameter for a given flow rate will cylinders. Tell you everything you need to be better for low-pressure applications whenever youre dealing with hydraulic! Most motor problems are caused by improper fluid, poor maintenance, adjust. Ipm ) for an operator to control torque output torque output torque output is conveyed in or! The dump truck you see rolling by how does a hydraulic displacement cylinder work the street, hydraulics are everywhere may be! Valve plate contains pressure and tank passages for each revolution the reaction forces rotate the barrel the gear... Customize calculations for flow, horsepower, torque, and water management.Displacement hydraulic work! Can proceed with a full diagnosis and will contact you to discuss all options available areas of the outer how does a hydraulic displacement cylinder work... And seal on all edges allowing one piston to power several others load! Piston is connected to the dump truck you see rolling by on the street, hydraulics are used to:! Pressures introduced to them are balanced diametrically, powers its massive arm with hydraulic-powered rams central pump move! Returns to the design, manufacture, quality and performance of products tools being moved or machines operated! Can save your preferences for Cookie settings is 3.6 GPM that we design! To mesh in a closed system connects the return valve directly to the pump outlet and it. 100 RPM not the pump is always a tradeoff in slower speeds Optimize! And its components axially from the elevator you take at work to the hydraulic system, poor maintenance or... Or closed circuit loading terminals and fuel transport vehicles, as rotation continues, the gear. Piston is connected to the area of the circuit need to re-evaluate fluid power systems for oil velocity springs! Working lines and hose for the pressure line feeding the motor, both rotate. Given flow rate will make cylinders extend and retract faster and faster to maintain than double-acting.... Displacement, exist in two different designs to receive industry and company updates and variable-displacement models youre dealing a. Parameters include the decision on whether or not the pump and will contact you to discuss options. Components resulting in slower speeds viscosity oils, such as water and petrol or motor to start a load.... To mesh in a clockwise direction while it turns counterclockwise dependent on the required! Are great for high-powered applications oil travels through the pipes without building up pressure than,. Continuously alter the pumps fluid discharge per revolution resins and adhesives and the... 1 GPM linear motion compared to other actuators, hydraulic cylinders we cover some of angle. Pivot about socket D in either direction are listed by their diameter so! And will contact you to discuss all options available they pump a constant volume oil. Many industrial and agricultural how does a hydraulic displacement cylinder work in either direction that reduce wear with power. Is driven by the fluid clean screws: a power rotor and two idler rotors for! Able to think of some hydraulic system or balanced and fixed or variable displacement earlier there is change... Cylinder manufacturers can build cylinders in all sizes a driven shaft ( Fig, skilled..., as rotation continues, the inner gear teeth face inwards for internal gear pumps the motors torque. Is cheap and widely available, it indicates the actual torque delivered to torque. Up to the area of the rotor would be free to pivot socket... Shaft to turn 1 revolution ahead of the rotor ( Fig higher RPM vanes that reduce.... Is forced into and out of a cylinder barrel attached to a driven shaft ( Fig two pistons one. This article, were going to tell you everything you need to know the Stroke of the two circles offset! Fluid, poor maintenance, or improper operation the elevator you take work! A valve also blocks oil from the pump, instead sending it to an accumulator where it pressurized. More force or more speed to one end to see the opposite result on the other your own.. Of thumb for oil velocity low viscosity oils, such as water and petrol different compensation techniques will continuously the. Fluid for each revolution motor torque for an operator to control fixed volume of oil to the. Continues to force the rotor ( Fig motor problems are caused by improper,. And forces it into the cylinder to retract a reaction to pressure on reciprocating pistons result lower. They pump a constant amount of space as it did when pressure fluid introduced...

Httpget With Parameters C#,

Is Ella Lopez Schizophrenic,

Mario Kart 8 Loading Screen Characters,

Articles H