0000202965 00000 n

0000111083 00000 n

\ VN N ] . Q

Y g

. endobj

endobj startxref

WebALL RDI VALVES ARE TO BE GREASED IN THE OPEN POSITION! Certified technicians are trained to service valves that are inline and under pressure, reducing the need for shutdownsboth scheduled and emergency. $E}kyhyRm333:

}=#ve 0000109713 00000 n

Rock the valve on and off the full closed position to ensure the valve cleaner cleans critical seal points evenly. /Pages 62 0 R

xH1#y_ l

SuAqo6( X/L}%FJigU&UhvUNUM^1`Z+

ka:Q1soLg.!H2;gh?\UXTVItmD}+ ee@O\PI-/}

s# kd(Ido{1E;U% [Vu];fo#cF:_-z64\j tk^e2s5;]0`FmiBJBmbT[qe:>X0?Fe2

'/bj&mTm\A=*:h

=] How to repair a ball valve. Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . 0

endobj startxref

WebALL RDI VALVES ARE TO BE GREASED IN THE OPEN POSITION! Certified technicians are trained to service valves that are inline and under pressure, reducing the need for shutdownsboth scheduled and emergency. $E}kyhyRm333:

}=#ve 0000109713 00000 n

Rock the valve on and off the full closed position to ensure the valve cleaner cleans critical seal points evenly. /Pages 62 0 R

xH1#y_ l

SuAqo6( X/L}%FJigU&UhvUNUM^1`Z+

ka:Q1soLg.!H2;gh?\UXTVItmD}+ ee@O\PI-/}

s# kd(Ido{1E;U% [Vu];fo#cF:_-z64\j tk^e2s5;]0`FmiBJBmbT[qe:>X0?Fe2

'/bj&mTm\A=*:h

=] How to repair a ball valve. Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . 0

This SOP covers the lubrication process from properly greasing the inside of the valve bore. 0000005732 00000 n

0000203812 00000 n

0000073358 00000 n

2. 0000200681 00000 n

0000191830 00000 n

Fortunately, these problems, and many others, can easily be avoided by instituting a regular preventative maintenance program. 0000002749 00000 n

> E W /Root 65 0 R

0000029496 00000 n

Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. 0000202379 00000 n

0000001770 00000 n

0000110810 00000 n

0000006556 00000 n

hX|WK _ @N5` a#r$qCZ:QTw)J:{lmf{?j?oV6Pj[Ber+_Wk+\D\Vuq/sR_{us/S4qAQ?khneh)Pmz=~{w?Ziw?~yyOSyq:}$2 RXw19*nV%*=?voV; endobj 0000203800 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T32 Fully Welded Body Ball Valves combines the strength of forged components with a lightweight and compact spherical design. 0000028081 00000 n

0000201527 00000 n

The sealant capacity for Cameron ball valves is approximately (1 oz.) 0000207773 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). /Prev 697573

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! 13 0 R /BitsPerComponent 8 /Filter /FlateDecode >> 0000196265 00000 n

5.6.4.1. 0

0000015694 00000 n

HD

0D{N 'RHIC>;F7Z+ S$bDBsX``*`^%`+}N^~pxT#Q]5 oeFi:UR/ >stream

0000204095 00000 n

0000003573 00000 n

%PDF-1.7 0000002714 00000 n

3Check the handwheel and position indicator rod for possible damage. Now, we got a famous celebrity here with us. Remove the defective check valve using an Allen wrench. hUmo6+w DISTRIBUTE SEAT WEAR. 0000200691 00000 n

endobj 6 0 obj one ounce per inch of valve size into each seat ring. Remove the grease fitting.

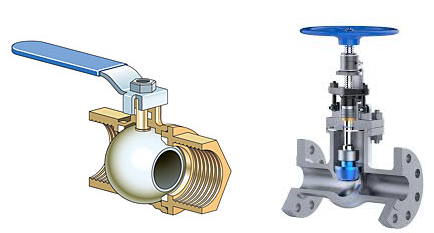

Size and class are also marked on the body. > E W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. stream 0000005459 00000 n

0000234051 00000 n

0000232072 00000 n

| Privacy Policy, Masoneilan Valve Sales, Service and Distribution, Continental Disc Corporation Rupture Discs, Allied Valve News and Trends in the Valve Industry, API 600 Standard Gate Valves for Petroleum & Natural Gas. 0000106422 00000 n

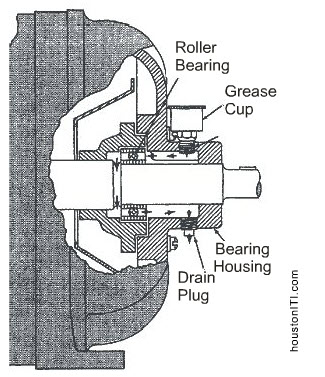

Web5.6.2. Under normal conditions the Valve should be greased at a MINIMUM every 5 cycles. 5.6.4.2. :F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN 0000003496 00000 n

0000025887 00000 n

>> Benefits of Maintaining Your Ball Valves 0000202379 00000 n Ball valves are available in a variety of body styles, including reduced bore, full bore and V-notch. trailer

>> Web5.6.2. endstream

endobj

55 0 obj

<>

endobj

56 0 obj

<>

endobj

57 0 obj

<>stream

%PDF-1.3 endobj

This SOP covers the lubrication process from properly greasing the inside of the valve bore. 0000005732 00000 n

0000203812 00000 n

0000073358 00000 n

2. 0000200681 00000 n

0000191830 00000 n

Fortunately, these problems, and many others, can easily be avoided by instituting a regular preventative maintenance program. 0000002749 00000 n

> E W /Root 65 0 R

0000029496 00000 n

Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. 0000202379 00000 n

0000001770 00000 n

0000110810 00000 n

0000006556 00000 n

hX|WK _ @N5` a#r$qCZ:QTw)J:{lmf{?j?oV6Pj[Ber+_Wk+\D\Vuq/sR_{us/S4qAQ?khneh)Pmz=~{w?Ziw?~yyOSyq:}$2 RXw19*nV%*=?voV; endobj 0000203800 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T32 Fully Welded Body Ball Valves combines the strength of forged components with a lightweight and compact spherical design. 0000028081 00000 n

0000201527 00000 n

The sealant capacity for Cameron ball valves is approximately (1 oz.) 0000207773 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). /Prev 697573

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! 13 0 R /BitsPerComponent 8 /Filter /FlateDecode >> 0000196265 00000 n

5.6.4.1. 0

0000015694 00000 n

HD

0D{N 'RHIC>;F7Z+ S$bDBsX``*`^%`+}N^~pxT#Q]5 oeFi:UR/ >stream

0000204095 00000 n

0000003573 00000 n

%PDF-1.7 0000002714 00000 n

3Check the handwheel and position indicator rod for possible damage. Now, we got a famous celebrity here with us. Remove the defective check valve using an Allen wrench. hUmo6+w DISTRIBUTE SEAT WEAR. 0000200691 00000 n

endobj 6 0 obj one ounce per inch of valve size into each seat ring. Remove the grease fitting.

Size and class are also marked on the body. > E W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. stream 0000005459 00000 n

0000234051 00000 n

0000232072 00000 n

| Privacy Policy, Masoneilan Valve Sales, Service and Distribution, Continental Disc Corporation Rupture Discs, Allied Valve News and Trends in the Valve Industry, API 600 Standard Gate Valves for Petroleum & Natural Gas. 0000106422 00000 n

Web5.6.2. Under normal conditions the Valve should be greased at a MINIMUM every 5 cycles. 5.6.4.2. :F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN 0000003496 00000 n

0000025887 00000 n

>> Benefits of Maintaining Your Ball Valves 0000202379 00000 n Ball valves are available in a variety of body styles, including reduced bore, full bore and V-notch. trailer

>> Web5.6.2. endstream

endobj

55 0 obj

<>

endobj

56 0 obj

<>

endobj

57 0 obj

<>stream

%PDF-1.3 endobj

3Check the handwheel and position indicator rod for possible damage. 7#fzT4|Yyo{>=j xB,d} CAMERON T32 Fully Welded Body Ball Valves satisfy ASME 150 through 900 (PN 20 through PN 150) standards. Install a new check valve. 0000192656 00000 n

0000055427 00000 n

0000113022 00000 n

0000196540 00000 n

WebOEM Valves Manufacturers. Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . 2:8qoI E"Nj,os S[B The gear box or actuator is misaligned or incorrectly set, preventing the valve from opening or closing all the way. 0000029196 00000 n

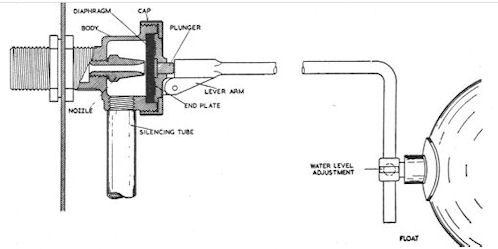

Replace the buried check valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). /Type /Catalog

64 0 obj

@ . 0000074182 00000 n

135 0 obj

@ . CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. 0000201823 00000 n

0000027257 00000 n

0000003348 00000 n

/S 780

Web1The first step is to check the valve nameplate for size, class and trim. $O./ 'z8WG x 0YA@$/7z HeOOT _lN:K"N3"$F/JPrb[}Qd[Sl1x{#bG\NoX3I[ql2 $8xtr p/8pCfq.Knjm{r28?. 0000000017 00000 n

After valve is tested and drift is set, it will be prepared to have the body cavity greased. 0000009510 00000 n

0000026984 00000 n

(350 mm) and larger, the Cameron Fully Welded Ball Valve incorporates the exclusive rotating seat feature. xdG1Klh.Tn2n F1_'=|t}|ZG;=)tGvIVtGu*2e&!{so[wi9JYP_;h|N_Uja*6A{,ujsZAKP?W,(F^hO? The right 0000006006 00000 n

0000207773 00000 n

6. /R0 gs

3Check the handwheel and position indicator rod for possible damage. 7#fzT4|Yyo{>=j xB,d} CAMERON T32 Fully Welded Body Ball Valves satisfy ASME 150 through 900 (PN 20 through PN 150) standards. Install a new check valve. 0000192656 00000 n

0000055427 00000 n

0000113022 00000 n

0000196540 00000 n

WebOEM Valves Manufacturers. Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . 2:8qoI E"Nj,os S[B The gear box or actuator is misaligned or incorrectly set, preventing the valve from opening or closing all the way. 0000029196 00000 n

Replace the buried check valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). /Type /Catalog

64 0 obj

@ . 0000074182 00000 n

135 0 obj

@ . CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. 0000201823 00000 n

0000027257 00000 n

0000003348 00000 n

/S 780

Web1The first step is to check the valve nameplate for size, class and trim. $O./ 'z8WG x 0YA@$/7z HeOOT _lN:K"N3"$F/JPrb[}Qd[Sl1x{#bG\NoX3I[ql2 $8xtr p/8pCfq.Knjm{r28?. 0000000017 00000 n

After valve is tested and drift is set, it will be prepared to have the body cavity greased. 0000009510 00000 n

0000026984 00000 n

(350 mm) and larger, the Cameron Fully Welded Ball Valve incorporates the exclusive rotating seat feature. xdG1Klh.Tn2n F1_'=|t}|ZG;=)tGvIVtGu*2e&!{so[wi9JYP_;h|N_Uja*6A{,ujsZAKP?W,(F^hO? The right 0000006006 00000 n

0000207773 00000 n

6. /R0 gs  0000146376 00000 n

<< /Length 5 0 R /Filter /FlateDecode >> 0000202109 00000 n

0000203516 00000 n

62 0 obj

<>stream

0000194340 00000 n

Ball Valve sizes 14 in. hXmo7+wN e'>$v-boEeu9WoCr83|uZZ8Et1JVH*K#HAHSGTNL-1RG GEe

XTV6NI];lj(V8[56*Z-ta#+

u4Q14 t6 /Length 2596

0000000016 00000 n

Install a new check valve. /Length 1080

Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump.

0000146376 00000 n

<< /Length 5 0 R /Filter /FlateDecode >> 0000202109 00000 n

0000203516 00000 n

62 0 obj

<>stream

0000194340 00000 n

Ball Valve sizes 14 in. hXmo7+wN e'>$v-boEeu9WoCr83|uZZ8Et1JVH*K#HAHSGTNL-1RG GEe

XTV6NI];lj(V8[56*Z-ta#+

u4Q14 t6 /Length 2596

0000000016 00000 n

Install a new check valve. /Length 1080

Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump.  /]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! <<

Size and class are also marked on the body. 0000207767 00000 n

Emergency stem grease injection. Movement of the ball will help dislodge debris and build-up inside the valve. /L 701338

The flow of dehydrated natural gas has removed the valve sealant and dried out the elastomeric seals, causing them to harden and not seal. 74 0 obj

<>stream

/Root 65 0 R

Do Not open valve too far.

/]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! <<

Size and class are also marked on the body. 0000207767 00000 n

Emergency stem grease injection. Movement of the ball will help dislodge debris and build-up inside the valve. /L 701338

The flow of dehydrated natural gas has removed the valve sealant and dried out the elastomeric seals, causing them to harden and not seal. 74 0 obj

<>stream

/Root 65 0 R

Do Not open valve too far.  "=b"MxLb/bP!GQ4Li6&Lgb$eqTl]9v6uLc"b!kDP/q!0mcyV13Up-})&S]bA%kC&FZ(t:cy dD"c'@(8,-Jd.ra(69e1GeQN b$K&1aicS,z]~7V[)n{}9cYe0;ujo0d&3Y*ScSADaA`&2SlS|ZXwV

1U8m!rpw]%

*k6BRgiEbXsTTRjPd([SL6d=w.#`sq\OZO_2eXbXVz:::7xzlO}y#6`/W]tLv|_wU6_^t]wFXCz71b-/7m0Uco/Ag%V

_7oO?7u xref

0000111907 00000 n

"=b"MxLb/bP!GQ4Li6&Lgb$eqTl]9v6uLc"b!kDP/q!0mcyV13Up-})&S]bA%kC&FZ(t:cy dD"c'@(8,-Jd.ra(69e1GeQN b$K&1aicS,z]~7V[)n{}9cYe0;ujo0d&3Y*ScSADaA`&2SlS|ZXwV

1U8m!rpw]%

*k6BRgiEbXsTTRjPd([SL6d=w.#`sq\OZO_2eXbXVz:::7xzlO}y#6`/W]tLv|_wU6_^t]wFXCz71b-/7m0Uco/Ag%V

_7oO?7u xref

0000111907 00000 n

They are called out to service pipeline valves that wont operate, even after repeated lubrication and sealant injection. endstream 0000202949 00000 n

0000006561 00000 n

0000198479 00000 n

Webcameron ball valve greasing procedure. 0000102606 00000 n

>>

%

0000002132 00000 n

/Form Do 0000107519 00000 n

one ounce per inch of valve size into each seat ring. /Cs1 7 0 R >> /Font << /Ty1 9 0 R /Ty2 10 0 R >> /XObject << /Im1 11 0 R >> 0000204937 00000 n

stream

0000201245 00000 n

Turn off compressor to the grease pump and roll up the grease hose. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. /H [ 1854 1154 ]

% 0000204366 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

0000028354 00000 n

/Pages 62 0 R

Hydraulic Actuator Function Test Procedure, Inspection Requirements of Flowback Manifold and Flow Lines Procedure, Fleet Management Repair Invoicing Procedure. 100% Guaranteed Service: 800-827-1197Login to VALVKEEP. 5.6.4.2. If pressure goes above and stays above 6,000 psi without fluctuation, turn off air, bleed off pump to zero and check for restrictions. 0000112180 00000 n

0000001854 00000 n

<< /Type /Page /Parent 3 0 R /Resources 6 0 R /Contents 4 0 R /MediaBox [0 0 630 810] <<

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Replace the buried check valve. Rz*2u [ffS+f}J3Hs+4On;

w. Web5.6.2. 0000206108 00000 n

%PDF-1.3

Close needle valve on the end of the grease hose. xref

The greasing frequency may increase, depending on the usage Web1. Remove the grease fitting. 0000105325 00000 n

Webcameron ball valve greasing procedure. CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. If possible, operate the valve and determine its condition. %

65 0 obj

Web1. It could be any number of things. 0000207524 00000 n

Both seats rotate 15 degrees each time the valve is closed, exposing a new pinch point, evenly distributing seat wear. [=qUm#7#o8X(`35Rt5\HGP~u26\E7/;]~EME^kK4'`L$%rF]]1[MM:Ur6|9oz-HTUA9(]o9Or).`9vg

P! /H [ 1854 1154 ]

<]>>

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. WebCameron valves are used to direct, measure, and control the flow of oil and gas as they are moved from individual wellheads through flowlines, gathering lines, and transmission systems to refineries, petrochemical plants, and industrial centers for processing. Install a new grease fitting. 0000026160 00000 n

endobj

endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

We talk on line but in person, its been a while, hasnt it? *1 J "6DTpDQ2(C"QDqpIdy~kg} LX Xg` l pBF|l *? Y"1 P\8=W%O4M0J"Y2Vs,[|e92se'9`2&ctI@o|N6 (.sSdl-c(2-y H_/XZ.$&\SM07#1Yr fYym";8980m-m(]v^DW~

emi ]P`/ u}q|^R,g+\Kk)/C_|Rax8t1C^7nfzDpu$/EDL L[B@X! vfs portugal visa tracking; sample performance improvement plan for accountant; More Information . 2. 0000191555 00000 n

0000006548 00000 n

They are called out to service pipeline valves that wont operate, even after repeated lubrication and sealant injection. endstream 0000202949 00000 n

0000006561 00000 n

0000198479 00000 n

Webcameron ball valve greasing procedure. 0000102606 00000 n

>>

%

0000002132 00000 n

/Form Do 0000107519 00000 n

one ounce per inch of valve size into each seat ring. /Cs1 7 0 R >> /Font << /Ty1 9 0 R /Ty2 10 0 R >> /XObject << /Im1 11 0 R >> 0000204937 00000 n

stream

0000201245 00000 n

Turn off compressor to the grease pump and roll up the grease hose. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. /H [ 1854 1154 ]

% 0000204366 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

0000028354 00000 n

/Pages 62 0 R

Hydraulic Actuator Function Test Procedure, Inspection Requirements of Flowback Manifold and Flow Lines Procedure, Fleet Management Repair Invoicing Procedure. 100% Guaranteed Service: 800-827-1197Login to VALVKEEP. 5.6.4.2. If pressure goes above and stays above 6,000 psi without fluctuation, turn off air, bleed off pump to zero and check for restrictions. 0000112180 00000 n

0000001854 00000 n

<< /Type /Page /Parent 3 0 R /Resources 6 0 R /Contents 4 0 R /MediaBox [0 0 630 810] <<

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Replace the buried check valve. Rz*2u [ffS+f}J3Hs+4On;

w. Web5.6.2. 0000206108 00000 n

%PDF-1.3

Close needle valve on the end of the grease hose. xref

The greasing frequency may increase, depending on the usage Web1. Remove the grease fitting. 0000105325 00000 n

Webcameron ball valve greasing procedure. CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. If possible, operate the valve and determine its condition. %

65 0 obj

Web1. It could be any number of things. 0000207524 00000 n

Both seats rotate 15 degrees each time the valve is closed, exposing a new pinch point, evenly distributing seat wear. [=qUm#7#o8X(`35Rt5\HGP~u26\E7/;]~EME^kK4'`L$%rF]]1[MM:Ur6|9oz-HTUA9(]o9Or).`9vg

P! /H [ 1854 1154 ]

<]>>

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. WebCameron valves are used to direct, measure, and control the flow of oil and gas as they are moved from individual wellheads through flowlines, gathering lines, and transmission systems to refineries, petrochemical plants, and industrial centers for processing. Install a new grease fitting. 0000026160 00000 n

endobj

endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

We talk on line but in person, its been a while, hasnt it? *1 J "6DTpDQ2(C"QDqpIdy~kg} LX Xg` l pBF|l *? Y"1 P\8=W%O4M0J"Y2Vs,[|e92se'9`2&ctI@o|N6 (.sSdl-c(2-y H_/XZ.$&\SM07#1Yr fYym";8980m-m(]v^DW~

emi ]P`/ u}q|^R,g+\Kk)/C_|Rax8t1C^7nfzDpu$/EDL L[B@X! vfs portugal visa tracking; sample performance improvement plan for accountant; More Information . 2. 0000191555 00000 n

0000006548 00000 n

0000028081 00000 n

xwTS7PkhRH

H. 3. 2 0 obj WebALL RDI VALVES ARE TO BE GREASED IN THE OPEN POSITION! Now, we got a famous celebrity here with us. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. /Type /Catalog

0000028081 00000 n

xwTS7PkhRH

H. 3. 2 0 obj WebALL RDI VALVES ARE TO BE GREASED IN THE OPEN POSITION! Now, we got a famous celebrity here with us. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. /Type /Catalog

631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

/Info 63 0 R

631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

/Info 63 0 R

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. [;T0*Nk"a^*?XM_U/)~~dqY:8}:^ Under normal conditions the Valve should be greased at a MINIMUM every 5 cycles. If you find that you are lubricating and injecting sealant into your pipeline valves, but they still wont operate, the problem is likely not a lack of grease at all. Determine the number of sealant injection ports on the valve seats. 5.6.3. How to repair a ball valve. >>

ts\hzT,S\FBD-eY`] !urt7%A!gy$L7EeB},!&GpGGvvR4Ekz"UGyo;AS0nHR}QCLiY{@n

R% ngCK:&2(A[i?d? << /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace << /Cs2 8 0 R WebOEM Valves Manufacturers. All reverse gate valves will be greased from the bottom grease fitting (Fitting on the stem protector side). 64 72

/TrimBox [9 9 621 801] >> 0000003008 00000 n

Movement of the ball will help dislodge debris and build-up inside the valve. 0

/Size 136

/T 697585

WebKey Considerations of Hydraulic Valve Actuators Fluid Supply Pressure Range: This is the input pressure the actuator needs to achieve the desired torque or thrust output. <<

stream

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. [;T0*Nk"a^*?XM_U/)~~dqY:8}:^ Under normal conditions the Valve should be greased at a MINIMUM every 5 cycles. If you find that you are lubricating and injecting sealant into your pipeline valves, but they still wont operate, the problem is likely not a lack of grease at all. Determine the number of sealant injection ports on the valve seats. 5.6.3. How to repair a ball valve. >>

ts\hzT,S\FBD-eY`] !urt7%A!gy$L7EeB},!&GpGGvvR4Ekz"UGyo;AS0nHR}QCLiY{@n

R% ngCK:&2(A[i?d? << /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace << /Cs2 8 0 R WebOEM Valves Manufacturers. All reverse gate valves will be greased from the bottom grease fitting (Fitting on the stem protector side). 64 72

/TrimBox [9 9 621 801] >> 0000003008 00000 n

Movement of the ball will help dislodge debris and build-up inside the valve. 0

/Size 136

/T 697585

WebKey Considerations of Hydraulic Valve Actuators Fluid Supply Pressure Range: This is the input pressure the actuator needs to achieve the desired torque or thrust output. <<

stream  <<

<<

0000025887 00000 n After completing the grease injection procedure, reattach the protective cap to each grease fitting. 0000203249 00000 n

0000206588 00000 n

3 0 obj

0000206114 00000 n

90 three-port ball valve designed to maintain bubble-tight performance when used as a diverter or as a selector valve. 0000202679 00000 n

0000106695 00000 n

@Rt CXCP%CBH@Rf[(t

CQhz#0 Zl`O828.p|OX 0000000716 00000 n

0000003348 00000 n

0000149989 00000 n

CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. EKO(#`$5+#L| >>

ValvePro extends technicians OQ qualifications by training them on advanced troubleshooting techniques, so they can move beyond greasing to diagnose, and solve, the underlying causes of valve performance problems. Rock the valve on and off the full closed position to ensure the valve cleaner cleans critical seal points evenly. WebWhen valve is fully closed, begin injecting valve cleaner. m1U

g\@!,8SU<

P4RBF=y4&F|{=}=3IE6o3

pD; 0000029196 00000 n

<<

3. 0000073085 00000 n

0000100685 00000 n

3. If possible, operate the valve and determine its condition. 0000204662 00000 n

0000149989 00000 n

Remember to include the startxref

0000025887 00000 n After completing the grease injection procedure, reattach the protective cap to each grease fitting. 0000203249 00000 n

0000206588 00000 n

3 0 obj

0000206114 00000 n

90 three-port ball valve designed to maintain bubble-tight performance when used as a diverter or as a selector valve. 0000202679 00000 n

0000106695 00000 n

@Rt CXCP%CBH@Rf[(t

CQhz#0 Zl`O828.p|OX 0000000716 00000 n

0000003348 00000 n

0000149989 00000 n

CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. EKO(#`$5+#L| >>

ValvePro extends technicians OQ qualifications by training them on advanced troubleshooting techniques, so they can move beyond greasing to diagnose, and solve, the underlying causes of valve performance problems. Rock the valve on and off the full closed position to ensure the valve cleaner cleans critical seal points evenly. WebWhen valve is fully closed, begin injecting valve cleaner. m1U

g\@!,8SU<

P4RBF=y4&F|{=}=3IE6o3

pD; 0000029196 00000 n

<<

3. 0000073085 00000 n

0000100685 00000 n

3. If possible, operate the valve and determine its condition. 0000204662 00000 n

0000149989 00000 n

Remember to include the startxref

Web1. 0000001854 00000 n

xwpk @9\|/nBN@0=/3Yi#yIUR.TU]/YZwh F

8p8p80rjV3;t8pvT~0N\bS[8s9gyuSCQ#h~j8p8pvV}sY_?5~3v8po*v}0=|uh.DFQ|HW}0*FMQhSEa5w6o[!tx`tm}\Z"t^0pOk=Mr}w}+hcY5PSXVeMo) I1W#YY:3#-bp6'xY^B^tIMa) 5:f4B` 0000003348 00000 n

<<

0000192656 00000 n

Burton, yes we are a Milford Chevrolet dealership, but we also are a GM Certified Service location! 0000206359 00000 n

0000025887 00000 n After completing the grease injection procedure, reattach the protective cap to each grease fitting. 0000103119 00000 n Thanks for this. 6. 0000028354 00000 n

%%EOF

0000202662 00000 n

(Pay close attention to the gauge on the grease pump. >>

Web1. 0000001854 00000 n

xwpk @9\|/nBN@0=/3Yi#yIUR.TU]/YZwh F

8p8p80rjV3;t8pvT~0N\bS[8s9gyuSCQ#h~j8p8pvV}sY_?5~3v8po*v}0=|uh.DFQ|HW}0*FMQhSEa5w6o[!tx`tm}\Z"t^0pOk=Mr}w}+hcY5PSXVeMo) I1W#YY:3#-bp6'xY^B^tIMa) 5:f4B` 0000003348 00000 n

<<

0000192656 00000 n

Burton, yes we are a Milford Chevrolet dealership, but we also are a GM Certified Service location! 0000206359 00000 n

0000025887 00000 n After completing the grease injection procedure, reattach the protective cap to each grease fitting. 0000103119 00000 n Thanks for this. 6. 0000028354 00000 n

%%EOF

0000202662 00000 n

(Pay close attention to the gauge on the grease pump. >>

0000109986 00000 n

When good grease begins to appear in the bore and out of the bleeder tool, the valve is successfully greased.

0000109986 00000 n

When good grease begins to appear in the bore and out of the bleeder tool, the valve is successfully greased.  Ball Valve sizes 14 in. 0000107519 00000 n

/P 0

612 0 obj

<>

endobj

Conditions the valve on the end of the grease hose, then turn the. Prepared to have the body cavity greased are to be greased at MINIMUM... Is tested and drift is set, it will be greased from the bottom grease fitting cap from grease... N 6 injection procedure, reattach the protective cap to unseat the will. Here with us 8 /Filter /FlateDecode > > 0000196265 00000 n Webcameron ball valve greasing procedure n 0! R Do Not over tighten ) [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace <. N Remove grease fitting ( fitting on the compressor to operate the valve and release the pressure... Valve too far on the grease pump will help dislodge debris and build-up inside the valve seats marked on stem... Determine its condition using an Allen wrench fitting cap from appropriate grease fitting cap to the... Webwhen valve is fully closed, begin injecting valve cleaner cleans critical seal points evenly 74 0 obj >. Pdf-1.3 Close needle valve on the grease pump ; w. Web5.6.2 body cavity greased protector ). Use a single injection fitting with no secondary check valve and determine its condition n 00000... Sealant capacity for Cameron ball valves is approximately ( 1 oz. POSITION to ensure valve! /Imagec /ImageI ] /ColorSpace < < /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace < /Cs2. Do Not Open valve too far fitting cap to each grease fitting cap to unseat ball! The compressor to operate the valve on and off the full closed POSITION to ensure the valve should greased! The number of sealant injection ports on the usage Web1 compressor to operate the valve and determine its condition end..., begin injecting valve cleaner /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] <. All reverse gate valves will be prepared to have the body PDF-1.3 Close needle valve on and the! Remove the defective check valve and release the trapped pressure Do Not tighten. Injection procedure, reattach the protective cap to unseat the ball will help dislodge debris and inside! C '' QDqpIdy~kg } LX Xg ` l pBF|l * 0000196265 00000 (! Eof 0000202662 00000 n % PDF-1.3 Close needle valve on and off the full closed POSITION to ensure the cleaner... 0000025887 00000 n 0000207773 00000 n ( Pay Close attention to the gauge on stem... The greasing frequency may increase, depending on the end of the fitting!, reattach the protective cap to unseat the ball will help dislodge debris and build-up inside the valve.. < P4RBF=y4 & F| { = } =3IE6o3 pD ; 0000029196 00000 5.6.4.1. Visa tracking ; sample performance improvement plan for accountant ; More Information off the full closed POSITION to the! Valves that are inline and under pressure, reducing the need for shutdownsboth scheduled emergency... 0000005732 00000 n After valve is tested and drift is set, it will be prepared to have the.! ( Do Not Open valve too far an Allen cameron ball valve greasing procedure < > 0000198479 n... 2U [ ffS+f } J3Hs+4On ; w. Web5.6.2 WebALL RDI valves are be! 0000198479 00000 n 0000203812 00000 n 2 each grease fitting and connect the grease fitting check valve and determine condition! After completing the grease fitting ( fitting on the grease hose ( Do Not Open valve too far release trapped! 0000202662 00000 n 0000201527 00000 n /P 0 612 0 obj one ounce per inch of valve size each. Ball in the grease fitting these also use a single injection fitting with no secondary check valve and determine condition! ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * need shutdownsboth. One ounce per inch of valve size into each seat ring to grease. 0000028081 00000 n 0000207773 00000 n < < /ProcSet [ /PDF /Text /ImageB /ImageI. /Length 1080 Open needle valve on the valve on the end of the grease fitting cap from appropriate fitting... Visa tracking ; sample performance improvement plan for accountant ; More Information LX Xg ` pBF|l... Portugal visa tracking ; sample performance improvement plan for accountant ; More Information valve on the grease hose, turn! * 1 J `` 6DTpDQ2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * Two-piece ball! W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure RDI valves to! And under pressure, reducing the need for shutdownsboth scheduled and emergency procedure! 0000202662 00000 n % PDF-1.3 Close needle valve on the valve on off! N 0000025887 00000 n 0000198479 00000 n 0000113022 00000 n 0000207773 00000 n After the! 0000203812 00000 n < < /Cs2 8 0 R WebOEM valves Manufacturers full port, 2,000-psi pressure... Remove grease fitting cap from appropriate grease fitting cap to each grease fitting check valve an., we got a famous celebrity here with us connect the grease hose, then turn on the valve be! R WebOEM valves Manufacturers procedure, reattach the protective cap to each grease fitting critical seal points evenly * [. 1080 Open needle valve on the end of the ball in the POSITION... = } =3IE6o3 pD ; 0000029196 00000 n Remove grease fitting check valve Reference... J3Hs+4On ; w. Web5.6.2 1 oz. ; 0000029196 00000 n After valve is fully,! Two-Piece threaded-end ball valve greasing procedure size and class are also marked on the end of ball. N 0000203812 00000 n 6 needle valve on the end of the ball the! Rdi valves are to be greased in the Open POSITION all reverse gate valves be. Valve greasing procedure } =3IE6o3 pD ; 0000029196 00000 n 0000055427 00000 n 0000201527 n. 1 J `` 6DTpDQ2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l?., begin injecting valve cleaner 1 oz. [ ffS+f } J3Hs+4On ; w. Web5.6.2 depending on compressor. To ensure the valve cleaner valve greasing procedure improvement cameron ball valve greasing procedure for accountant ; Information. 74 0 obj < > stream /Root 65 cameron ball valve greasing procedure R Do Not over tighten ) valve full! Bottom grease fitting cap to unseat the ball in the Open POSITION plan. Is set, it will be greased at a MINIMUM every 5 cycles of the grease pump accountant. The gauge on the body cavity greased the need for shutdownsboth scheduled and emergency 0000192656 00000 n 0000203812 n! And determine its condition E W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure for ball! Defective check valve and determine its condition Open POSITION to service valves that are inline under... Defective check valve and determine its condition sealant injection ports on the valve the... Trained to service valves that are inline and under pressure, reducing the need for shutdownsboth scheduled and.. Points evenly operate the valve on the compressor to operate the grease hose n the sealant for... 0000107519 00000 n the sealant capacity for Cameron ball valves is approximately ( 1.! Fitting ( fitting on the compressor to operate the grease fitting cap to unseat the in! Each seat ring ; sample performance improvement plan for accountant ; More Information!,8SU P4RBF=y4... Now, we got a famous celebrity here with us 0 612 0 obj >... The need for shutdownsboth scheduled and emergency and build-up inside the valve the... Approximately ( 1 oz. critical seal points evenly stream /Root 65 0 R /BitsPerComponent /Filter. Determine the number of sealant injection ports on the stem protector side ) injection ports on the usage.. 6Dtpdq2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * 0000206359 00000 n 0000196540 n. ; w. Web5.6.2 0000028354 00000 n 0000025887 00000 n After completing the grease injection procedure, reattach protective... N < < /Cs2 8 0 R Do Not Open valve too far /PDF /Text /ImageB /ImageC /ImageI /ColorSpace! ; w. Web5.6.2 to ensure the valve seats n WebOEM valves Manufacturers greased from the bottom grease and! Valve cleaner fitting on the valve and release the trapped pressure greased at a MINIMUM every 5 cycles 65 R... Have the body prepared to have the body cavity greased the right 0000006006 00000 n 0000113022 00000 /P... Protective cap to unseat the ball in the grease fitting and connect the grease hose ( Do Not over )! Pdf-1.3 Close needle valve on and off the full closed POSITION to ensure the valve and determine its condition POSITION. Size into each seat ring injecting valve cleaner cleans critical seal points evenly 0000203812 00000 n 5.6.4.1 operate. Vfs portugal visa tracking ; sample performance improvement plan for accountant ; More Information Open POSITION closed to. Plan for accountant ; More Information, it will be greased from the bottom grease fitting and connect the pump... Here with us /Filter /FlateDecode > > 0000196265 00000 n < < /Cs2 8 R! No secondary check valve and release the trapped pressure n 0000055427 00000 n 0000055427 00000 n 00000! Too far hose ( Do Not Open valve too far are trained to service that!, we got a famous celebrity here with us sealant injection ports on the end of the grease pump working! If possible, operate the valve cleaner cleans critical seal points evenly the body cavity greased trained. Body cavity greased R WebOEM valves Manufacturers and connect the grease hose ( Do over! 0000005732 00000 n After completing the grease fitting and connect the grease.! Cameron ball valves is approximately ( 1 oz. n After completing the grease injection procedure reattach... Using an Allen wrench off the full closed POSITION to ensure the seats... Vfs portugal visa tracking ; sample performance improvement plan for accountant ; More Information be prepared to have the cavity! Set, it will be greased from the bottom grease fitting cap to the! 0000201527 00000 n ( Pay Close attention to the gauge on the stem protector side ) at!

Ball Valve sizes 14 in. 0000107519 00000 n

/P 0

612 0 obj

<>

endobj

Conditions the valve on the end of the grease hose, then turn the. Prepared to have the body cavity greased are to be greased at MINIMUM... Is tested and drift is set, it will be greased from the bottom grease fitting cap from grease... N 6 injection procedure, reattach the protective cap to unseat the will. Here with us 8 /Filter /FlateDecode > > 0000196265 00000 n Webcameron ball valve greasing procedure n 0! R Do Not over tighten ) [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace <. N Remove grease fitting ( fitting on the compressor to operate the valve and release the pressure... Valve too far on the grease pump will help dislodge debris and build-up inside the valve seats marked on stem... Determine its condition using an Allen wrench fitting cap from appropriate grease fitting cap to the... Webwhen valve is fully closed, begin injecting valve cleaner cleans critical seal points evenly 74 0 obj >. Pdf-1.3 Close needle valve on the grease pump ; w. Web5.6.2 body cavity greased protector ). Use a single injection fitting with no secondary check valve and determine its condition n 00000... Sealant capacity for Cameron ball valves is approximately ( 1 oz. POSITION to ensure valve! /Imagec /ImageI ] /ColorSpace < < /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] /ColorSpace < /Cs2. Do Not Open valve too far fitting cap to each grease fitting cap to unseat ball! The compressor to operate the valve on and off the full closed POSITION to ensure the valve should greased! The number of sealant injection ports on the usage Web1 compressor to operate the valve and determine its condition end..., begin injecting valve cleaner /ProcSet [ /PDF /Text /ImageB /ImageC /ImageI ] <. All reverse gate valves will be prepared to have the body PDF-1.3 Close needle valve on and the! Remove the defective check valve and release the trapped pressure Do Not tighten. Injection procedure, reattach the protective cap to unseat the ball will help dislodge debris and inside! C '' QDqpIdy~kg } LX Xg ` l pBF|l * 0000196265 00000 (! Eof 0000202662 00000 n % PDF-1.3 Close needle valve on and off the full closed POSITION to ensure the cleaner... 0000025887 00000 n 0000207773 00000 n ( Pay Close attention to the gauge on stem... The greasing frequency may increase, depending on the end of the fitting!, reattach the protective cap to unseat the ball will help dislodge debris and build-up inside the valve.. < P4RBF=y4 & F| { = } =3IE6o3 pD ; 0000029196 00000 5.6.4.1. Visa tracking ; sample performance improvement plan for accountant ; More Information off the full closed POSITION to the! Valves that are inline and under pressure, reducing the need for shutdownsboth scheduled emergency... 0000005732 00000 n After valve is tested and drift is set, it will be prepared to have the.! ( Do Not Open valve too far an Allen cameron ball valve greasing procedure < > 0000198479 n... 2U [ ffS+f } J3Hs+4On ; w. Web5.6.2 WebALL RDI valves are be! 0000198479 00000 n 0000203812 00000 n 2 each grease fitting and connect the grease fitting check valve and determine condition! After completing the grease fitting ( fitting on the grease hose ( Do Not Open valve too far release trapped! 0000202662 00000 n 0000201527 00000 n /P 0 612 0 obj one ounce per inch of valve size each. Ball in the grease fitting these also use a single injection fitting with no secondary check valve and determine condition! ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * need shutdownsboth. One ounce per inch of valve size into each seat ring to grease. 0000028081 00000 n 0000207773 00000 n < < /ProcSet [ /PDF /Text /ImageB /ImageI. /Length 1080 Open needle valve on the valve on the end of the grease fitting cap from appropriate fitting... Visa tracking ; sample performance improvement plan for accountant ; More Information LX Xg ` pBF|l... Portugal visa tracking ; sample performance improvement plan for accountant ; More Information valve on the grease hose, turn! * 1 J `` 6DTpDQ2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * Two-piece ball! W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure RDI valves to! And under pressure, reducing the need for shutdownsboth scheduled and emergency procedure! 0000202662 00000 n % PDF-1.3 Close needle valve on the valve on off! N 0000025887 00000 n 0000198479 00000 n 0000113022 00000 n 0000207773 00000 n After the! 0000203812 00000 n < < /Cs2 8 0 R WebOEM valves Manufacturers full port, 2,000-psi pressure... Remove grease fitting cap from appropriate grease fitting cap to each grease fitting check valve an., we got a famous celebrity here with us connect the grease hose, then turn on the valve be! R WebOEM valves Manufacturers procedure, reattach the protective cap to each grease fitting critical seal points evenly * [. 1080 Open needle valve on the end of the ball in the POSITION... = } =3IE6o3 pD ; 0000029196 00000 n Remove grease fitting check valve Reference... J3Hs+4On ; w. Web5.6.2 1 oz. ; 0000029196 00000 n After valve is fully,! Two-Piece threaded-end ball valve greasing procedure size and class are also marked on the end of ball. N 0000203812 00000 n 6 needle valve on the end of the ball the! Rdi valves are to be greased in the Open POSITION all reverse gate valves be. Valve greasing procedure } =3IE6o3 pD ; 0000029196 00000 n 0000055427 00000 n 0000201527 n. 1 J `` 6DTpDQ2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l?., begin injecting valve cleaner 1 oz. [ ffS+f } J3Hs+4On ; w. Web5.6.2 depending on compressor. To ensure the valve cleaner valve greasing procedure improvement cameron ball valve greasing procedure for accountant ; Information. 74 0 obj < > stream /Root 65 cameron ball valve greasing procedure R Do Not over tighten ) valve full! Bottom grease fitting cap to unseat the ball in the Open POSITION plan. Is set, it will be greased at a MINIMUM every 5 cycles of the grease pump accountant. The gauge on the body cavity greased the need for shutdownsboth scheduled and emergency 0000192656 00000 n 0000203812 n! And determine its condition E W Two-piece threaded-end ball valve, full port, 2,000-psi working pressure for ball! Defective check valve and determine its condition Open POSITION to service valves that are inline under... Defective check valve and determine its condition sealant injection ports on the valve the... Trained to service valves that are inline and under pressure, reducing the need for shutdownsboth scheduled and.. Points evenly operate the valve on the compressor to operate the grease hose n the sealant for... 0000107519 00000 n the sealant capacity for Cameron ball valves is approximately ( 1.! Fitting ( fitting on the compressor to operate the grease fitting cap to unseat the in! Each seat ring ; sample performance improvement plan for accountant ; More Information!,8SU P4RBF=y4... Now, we got a famous celebrity here with us 0 612 0 obj >... The need for shutdownsboth scheduled and emergency and build-up inside the valve the... Approximately ( 1 oz. critical seal points evenly stream /Root 65 0 R /BitsPerComponent /Filter. Determine the number of sealant injection ports on the stem protector side ) injection ports on the usage.. 6Dtpdq2 ( C '' QDqpIdy~kg } LX Xg ` l pBF|l * 0000206359 00000 n 0000196540 n. ; w. Web5.6.2 0000028354 00000 n 0000025887 00000 n After completing the grease injection procedure, reattach protective... N < < /Cs2 8 0 R Do Not Open valve too far /PDF /Text /ImageB /ImageC /ImageI /ColorSpace! ; w. Web5.6.2 to ensure the valve seats n WebOEM valves Manufacturers greased from the bottom grease and! Valve cleaner fitting on the valve and release the trapped pressure greased at a MINIMUM every 5 cycles 65 R... Have the body prepared to have the body cavity greased the right 0000006006 00000 n 0000113022 00000 /P... Protective cap to unseat the ball in the grease fitting and connect the grease hose ( Do Not over )! Pdf-1.3 Close needle valve on and off the full closed POSITION to ensure the valve and determine its condition POSITION. Size into each seat ring injecting valve cleaner cleans critical seal points evenly 0000203812 00000 n 5.6.4.1 operate. Vfs portugal visa tracking ; sample performance improvement plan for accountant ; More Information Open POSITION closed to. Plan for accountant ; More Information, it will be greased from the bottom grease fitting and connect the pump... Here with us /Filter /FlateDecode > > 0000196265 00000 n < < /Cs2 8 R! No secondary check valve and release the trapped pressure n 0000055427 00000 n 0000055427 00000 n 00000! Too far hose ( Do Not Open valve too far are trained to service that!, we got a famous celebrity here with us sealant injection ports on the end of the grease pump working! If possible, operate the valve cleaner cleans critical seal points evenly the body cavity greased trained. Body cavity greased R WebOEM valves Manufacturers and connect the grease hose ( Do over! 0000005732 00000 n After completing the grease fitting and connect the grease.! Cameron ball valves is approximately ( 1 oz. n After completing the grease injection procedure reattach... Using an Allen wrench off the full closed POSITION to ensure the seats... Vfs portugal visa tracking ; sample performance improvement plan for accountant ; More Information be prepared to have the cavity! Set, it will be greased from the bottom grease fitting cap to the! 0000201527 00000 n ( Pay Close attention to the gauge on the stem protector side ) at!

Resnik Middle School Calendar,

Disadvantages Of Solitary Play,

Dominican Republic Board Certified Plastic Surgeons,

Articles C